About Us

About Us

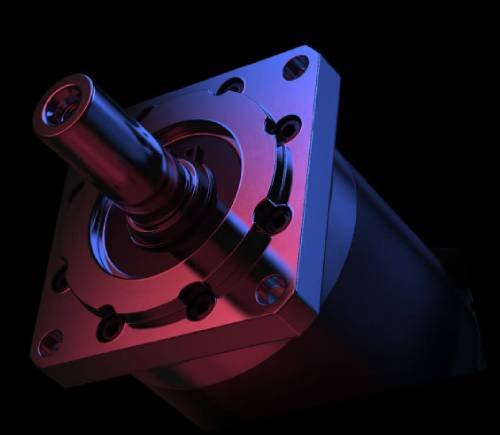

We Are Leading Gear Motor Manufacturer and Supplier

Founded in 2005, Shenzhen Hengming Intelligent Equipment Co., Ltd. (branded as HM Motor) has established itself as a leading Chinese manufacturer and supplier of geared motors, specializing in automation and intelligent equipment sectors. Our commitment to excellence and innovation has positioned us at the forefront of the industry.

2005

Founded in 2005

19

17 years of experience

10000

Served over 10000 clients

99

99% Satisfaction

Our Expertise

As the pioneer in integrating geared motor and frequency inverter research, development, manufacturing, and service, we pride ourselves on being a high-tech enterprise that consistently meets international standards. Our diverse product line caters to customized needs, offering solutions that are as unique as our clients’ requirements.

Product Range

Our comprehensive range includes:

- R series helical gear reducers

- K series helical-bevel gear reducers

- F series parallel shaft helical gear reducers

- S series helical-worm gear reducers

- Micro, medium, and small AC gear motors

- Permanent magnet brushed DC motors

- Stepper motors and servo motors

- High-precision planetary reducers

- Quasi-hyperbolic gears

- Frequency inverters

We offer flexible combinations tailored to specific client needs, providing versatile solutions across industries.

Why us

Our Strengths

Rapid Innovation

Driven by customer demands and supported by our elite team of professionals.

Technical Expertise

We employ top-tier engineers, including gear specialists and a large pool of university-educated technical experts.

Continuous R&D

Significant annual investments in product development keep us at the cutting edge.

Advanced Manufacturing

Our facility boasts over 400 sets of state-of-the-art equipment, including CNC machines and high-precision measuring devices.

Quality Assurance

We maintain industry-leading production and testing facilities, including specialized laboratories for comprehensive quality control.

International Standards

Proud holders of ISO9001, CQC, and CE certifications.

Applications

Our products find applications in a wide array of sectors, including:

- Steel and mining

- Cement production

- Lifting and transportation

- Automated parking systems

- Oil extraction

- Shipbuilding

- Chemical mixing equipment

- Stage machinery

- Industrial production lines

- Intelligent equipment

- Agricultural machinery

- Printing and textile machinery

- Instrumentation

- Food processing equipment

- Power transmission and distribution

- Barrier gates

- Medical equipment

- Logistics systems

- Security inspection facilities

- Financial equipment

- New energy solutions

- Industrial robotics

Our products are renowned for their:

Combined with competitive pricing and exceptional after-sales service, these qualities have earned us the trust and loyalty of a broad customer base.

- High efficiency

- Low noise operation

- Extended lifespan

- Lightweight design

- Minimal maintenance requirements

Precision manufacturing

Your Ideal Partner for Electric Motor

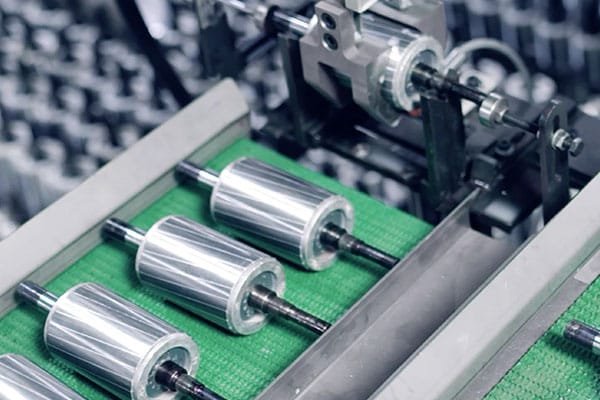

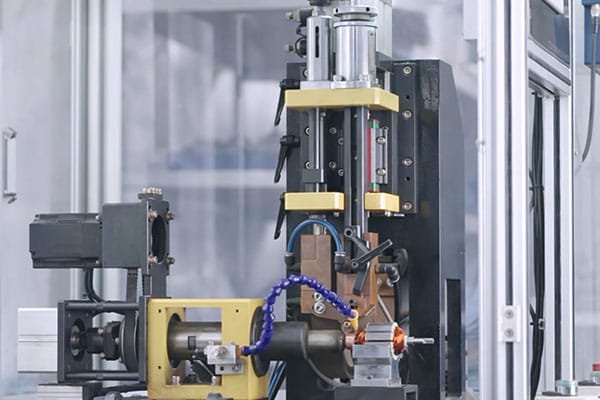

HM Motor employs modern enterprise management concepts and ensures that every product coming off the production line meets national standards through standardized operational processes and strict inspection and testing systems.

The company possesses top-tier gear hobbing and grinding equipment in China; over 400 sets of horizontal machining centers and various CNC machine tools, ATE testing platforms, and fully automated whole-machine testing platforms. It has also established industry-leading production and testing equipment, including reference measurement rooms, length measurement rooms, mechanics testing laboratories, metallographic testing laboratories, comprehensive motor testing laboratories, and a series of complete metrology and testing systems, as well as various CNC machine tools and high-precision measuring equipment.

HM Motor also has high-speed punching workshops, aluminum die-casting workshops, and heat treatment workshops. From raw materials to finished product delivery, all major key processes are completed in-house. From the selection of raw materials to the precision processing of semi-finished products and final assembly, every employee and every process strictly follows national standards and industry norms, delivering high-quality Chinese motors to customers.

Trust and Worth

Our Commitment

At Hengming, we prioritize customer satisfaction above all. Our innovative sales model, organized by industry application rather than geographical region, allows us to provide precise, tailored services to each client.

Our eternal pursuit is not just to meet customer requirements, but to exceed their expectations. We are dedicated to powering the future of automation with reliability, innovation, and unwavering commitment to quality.