Micro Motors

Micro Constant Speed Motor

About Us

Professional micro gear reducer supplier

HM Motor is a high-tech enterprise specializing in the development and manufacturing of micro constant-speed motors. We are committed to providing global customers with high-performance, reliable, and stable micro motor solutions. As an industry leader, we boast a strong R&D team and advanced production equipment to ensure that our products always remain at the forefront of technology.

Micro Constant Speed Motor Concept

What is a micro-speed constant-speed motor?

The micro-torque motor is a compact and powerful motor that is used for achieving precise speed control. It features a compact size and high efficiency, making it suitable for various application fields. The micro-torque motor is typically composed of two parts: a micro-motor and a controller, which together enable precise speed regulation and stable operation through electronic control technology.

The micro-torque motor is widely used in many fields, such as automation equipment, robotics technology, medical devices, precision instruments, optical equipment, and more. They provide high-precision position and speed control, which can be used to drive rotating platforms, precision positioning systems, and precise motion control for medical devices.

The micro-torque motor boasts advantages such as rapid response, high power density, and low noise. Its high-precision speed control can be achieved through a closed-loop feedback system, ensuring stability and accuracy. Furthermore, the micro-torque motor can communicate and integrate with other devices via digital interfaces to realize more advanced functions and system controls.

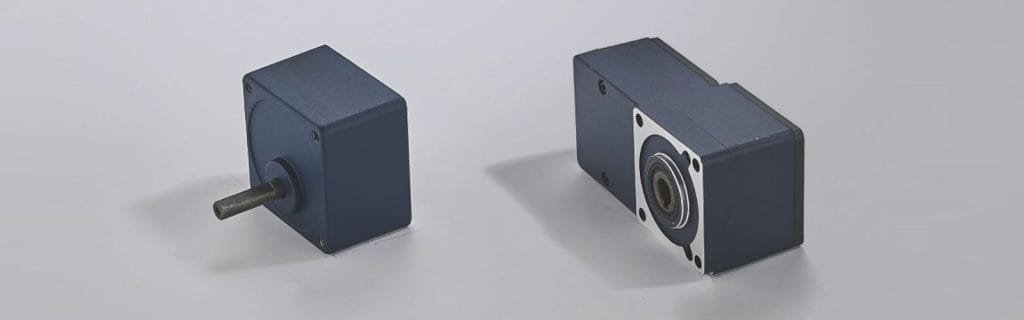

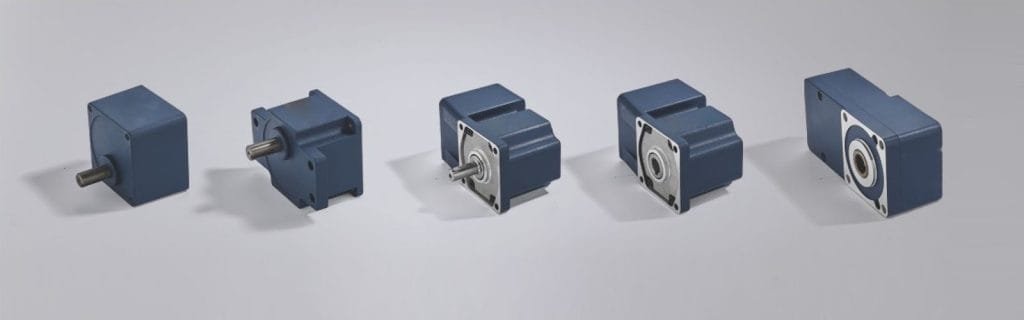

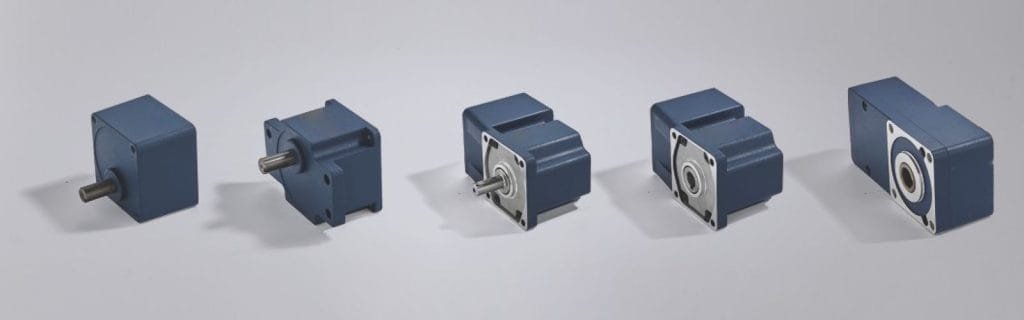

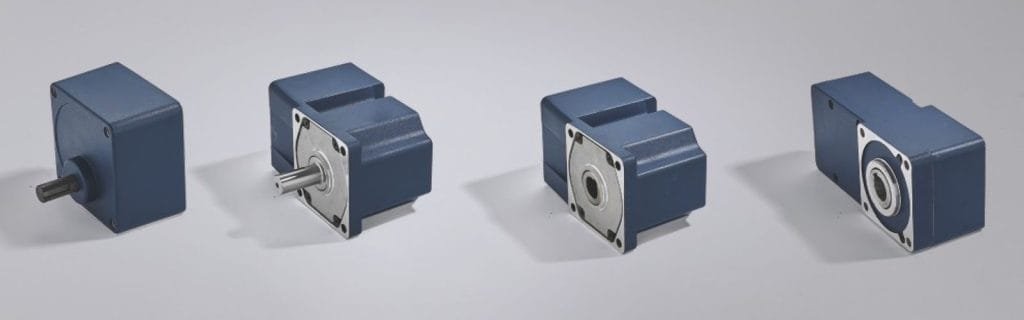

Series of micro and small-sized gear reduction motors

Micro constant speed motor models

"High quality, high standards, zero defects"

The company assembles a team of professional talents in production, technology, and sales with more than ten years of deep industry cultivation. The team is composed of individuals with shared aspirations and pursuits. The company endeavors to carry out innovative mechanisms such as technological innovation, manufacturing innovation, management innovation, and process innovation. It has a full set of imported and domestically produced production and testing equipment, integrated industrial production lines, an efficient and sound sales network, and after-sales service system, providing satisfactory products and services to both new and existing customers.

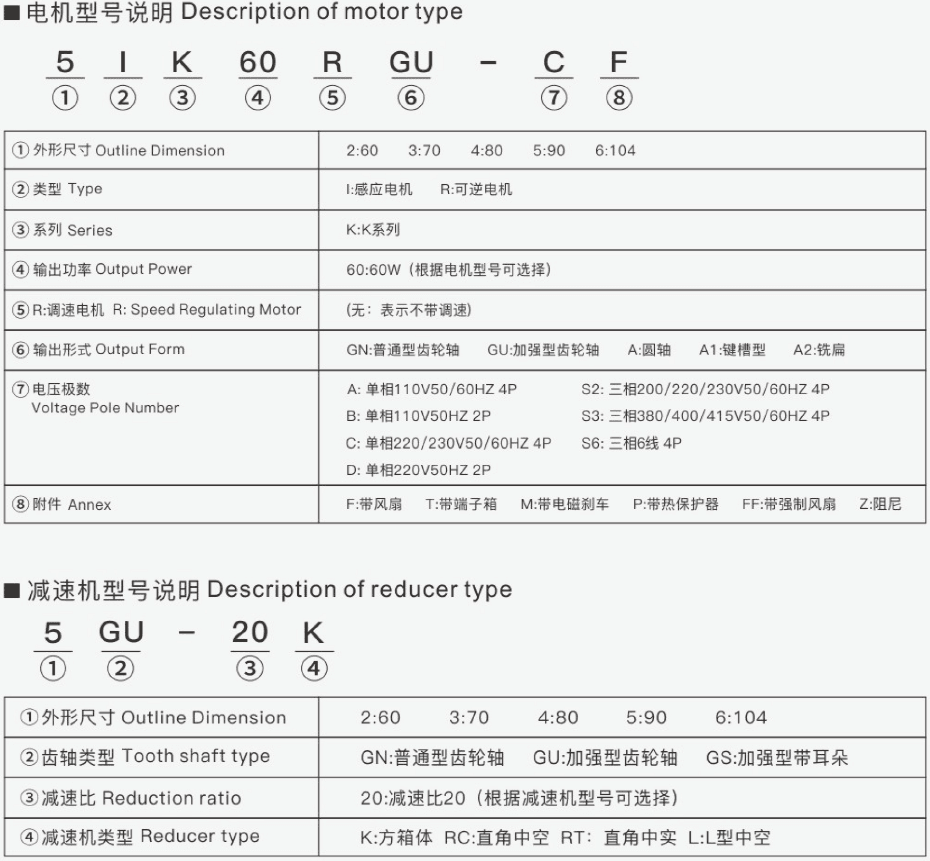

Motor Models and Types

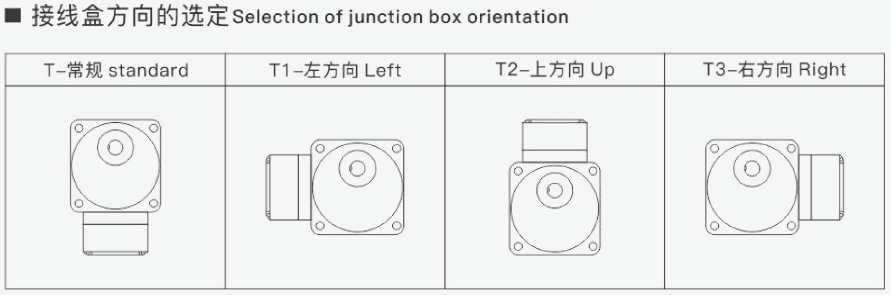

Selection of junction box orientation

Why choose us?

Characteristics of HM Motor Micro Constant-speed Motor

HM Motor’s series of micro constant-speed motors boast exceptional performance and a wide range of applications. Our products are characterized by the following features:

- High-Precision Control: Equipped with advanced control algorithms and high-precision encoders, HM Motor’s intelligent micro constant-speed motors offer precise speed control and positional feedback. Whether in industrial automation or consumer electronics, our products meet customers’ needs for accurate control.

- High Efficiency: Our micro constant-speed motors feature high-efficiency electromagnetic design and optimized transmission systems, enabling higher output power with lower energy consumption and a smaller footprint. This results in superior performance and longer lifespan across various applications.

- Diverse Options: We offer a variety of models and specifications of micro constant-speed motors to cater to diverse customer needs. From small appliances and medical devices to smart home equipment and robots, our products cover a broad range of applications.

- Reliability and Stability: HM Motor’s intelligent micro constant-speed motors undergo rigorous testing and quality control to ensure reliability and stability. Our products operate stably under various environmental conditions and can withstand high loads and impacts.

- Cost-Effectiveness: We are committed to delivering high value to our customers by offering cost-effective products. Both in terms of performance and pricing, we maintain competitiveness, providing customers with the most valuable options.

The excellent characteristics of HM Motor’s micro constant-speed motors make them the preferred choice in numerous industries. Customers can confidently select our products and rely on our technology and services to provide lasting power support for their projects.

We can always do better.

Starting from the details, we strictly control quality, emphasize the process management and control of quality advancement, and prevent the production of defective products. Additionally, we have established a comprehensive quality management system, with inspectors assigned to every production stage to inspect and evaluate products according to technical standards. In the finished product inspection process, professional testers conduct a full inspection of the appearance and operating performance of the products before they leave the factory, ensuring the quality of the outgoing products.

Notes

Micro Constant-Speed Motor Installation and Usage Precautions

General Information: Do not use the gearbox and motor beyond the specifications indicated on the nameplate or in the product catalog to avoid electric shock, injury, and damage to equipment. Do not insert fingers or objects into the opening parts of the gearbox or motor to prevent electric shock, injury, fire, and damage to equipment. Do not use damaged gearboxes or motors to avoid potential injury and fire hazards. Do not remove the nameplate. Any unauthorized modifications to the product by the customer will void the warranty, and our company will not bear any responsibility.

Handling: It is dangerous if the gearbox or motor falls or tips over during handling. Please be cautious.

Installation: Never place flammable materials around the gearbox and motor to prevent fires. Avoid placing objects around the motor that could obstruct ventilation and cooling, which may lead to overheating, burns, or fires. Do not touch the keyway of the gears or motor gear parts with bare hands to prevent injury. In food machinery or other equipment where oil leaks may occur, install an additional oil cup at the installation site to prevent potential adverse effects from oil leaks.

Connection to the Main Machinery: Set up safety guards around rotating parts to prevent injury. Before connecting to another machine, confirm the direction of rotation. Incorrect rotation may cause injury or damage to the equipment.

Wiring: When testing insulation resistance, do not touch the terminals to avoid electric shock.

Operation: Connect to the power source according to the wiring diagram or operating instructions to prevent electric shock or fire. (For units without a terminal box, ensure additional insulation at the connection points.) Do not excessively bend, stretch, or clamp the power cables and motor leads to avoid electric shock hazards. The grounding terminal should be securely grounded to prevent electric shock. Always use a power source that meets the specifications on the nameplate to avoid burning out the motor and causing a fire.

Routine Inspection and Maintenance: Never approach or touch rotating objects (shafts, etc.) during operation. If there is a risk of entanglement and injury, immediately cut off the power supply and take appropriate measures. During a power outage, always cut off the power supply to prevent injury or damage to equipment when power is restored. Note: Motors with thermal protection will automatically cut off the power when the motor temperature is abnormally high and will resume operation automatically when the temperature drops to a certain level. (Note: The motor will automatically recover if it has not been burned out.)

Inspection Upon Receiving Goods: Please confirm that the delivered goods match the order. Selecting the wrong product may damage the motor or equipment.

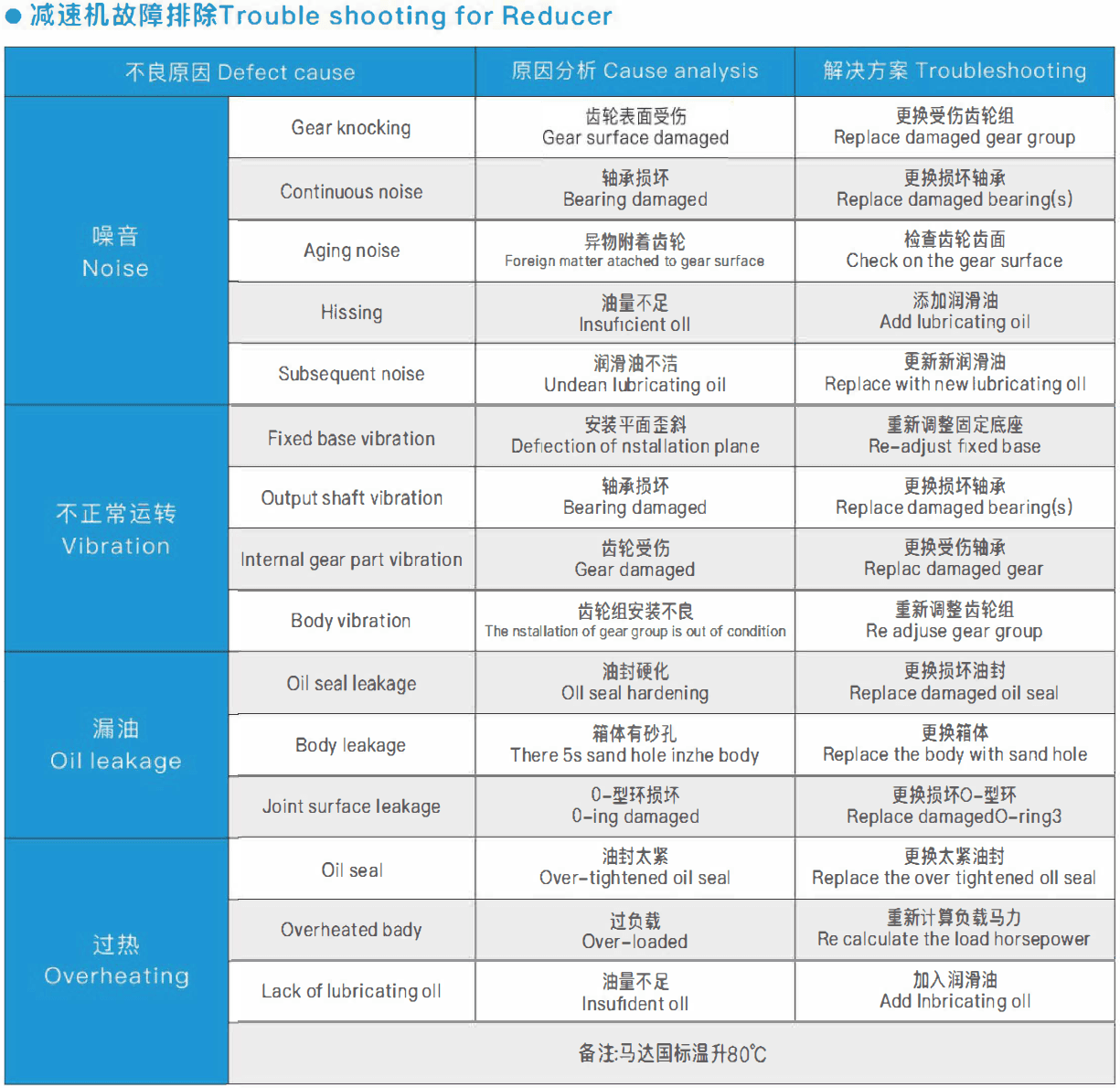

Trouble Shooting for Reducer

FAQs

Micro speed constant motors usually adopt electronic control technology, which achieves the adjustment of motor speed by controlling the current or voltage. They are typically composed of two parts: the motor body and the controller. The controller monitors the motor's speed in real-time through feedback signals and adjusts the current or voltage to achieve the desired speed control.

Selecting a suitable miniature variable-speed motor requires considering multiple factors, including the required speed range, load requirements, durability, and precision requirements. The motor's size and power density should also be taken into account to ensure it meets the spatial requirements and power consumption limitations of the specific application scenario.

The miniature constant-speed motor has the advantages of small size, fast response, high efficiency, and high precision control. They are suitable for various applications and can provide precise position and speed control, achieving stable and reliable operation.

High-precision control of micro-torque motors is typically achieved through closed-loop feedback systems. Feedback sensors, such as encoders, are used to monitor the motor's speed in real-time and send the feedback signal to the controller. The controller adjusts the current or voltage based on the feedback signal to make the motor reach the desired speed.

Micro variable-speed motors are widely used in fields such as automation equipment, robotics technology, medical devices, precision instruments, and optical equipment. They can be used to drive rotating platforms, precise positioning systems, and accurate motion control for medical devices.

通常, micro-speed motors do not require frequent maintenance and care. However, it is important to regularly check the operational status and temperature of the motor. Ensure good ventilation around the motor to prevent dust and particulate matter from entering. If abnormal noises, vibrations, or overheating are detected, the motor should be immediately stopped and inspected.

Micro-servo motors and variable-speed motors are two different types of electric motors, which differ in their working principles and functions. Below are some key characteristics that differentiate between constant-speed motors and variable-speed motors:

Working Principle: Constant-speed motors will operate at a constant speed regardless of load changes. On the other hand, variable-speed motors can adjust their output speed as needed to accommodate different load requirements.

Control Method: Constant-speed motors typically use open-loop control, which means maintaining a constant speed by applying a specific voltage and frequency. Variable-speed motors usually use closed-loop control, adjusting the output speed through sensor feedback.

Application Fields: Constant-speed motors are suitable for applications that require high speed consistency and have minimal load changes, such as clocks, instrument equipment, etc. Variable-speed motors are suitable for applications that need to adjust speed in real-time according to load changes, such as mechanical transmission systems, governors, etc.

Constant-speed motors and variable-speed motors are two different types of motors, which differ in terms of speed control. Below is a comparison of the differences between constant-speed motors and variable-speed motors:

Speed Control: The speed of a constant-speed motor is fixed and cannot be adjusted, operating at a constant speed at all times. On the other hand, a variable-speed motor has the ability to adjust its speed, allowing for the output speed to be changed as needed.

Control Methods: Constant-speed motors typically use open-loop control, which means maintaining a constant speed by providing a specific voltage and frequency. Variable-speed motors usually use closed-loop control, adjusting the output speed through sensor feedback to achieve precise speed regulation.

Application Scope: Constant-speed motors are suitable for applications with high speed requirements and minimal load changes, such as clocks and instrument equipment. Variable-speed motors are suitable for applications that require real-time speed adjustments based on load requirements, such as industrial production lines, fans, pumps, and so on.

1. Safety and Aesthetics: Protected by a micro junction box, with IP54 rating, wiring and replacement are more convenient, safer, and more aesthetically pleasing, enabling your product to better meet safety standards.

2. Rich in Models: With strong financial and technical capabilities, we offer rack bases ranging from 60-100mm in size, and power ratings from 6W to 200W.

3. Ultra-Low Noise: Precision helical gears are machined using high-precision gear cutting machines and AAA-grade cutting tools. The four corners of the four-box structure are designed with double-column high-rigidity, ensuring rigidity and non-deformation even under high-load conditions, with minimal vibration.

4. Ultra-Long Life: Gear materials are made of high-molybdenum alloy steel and are subjected to special heat treatment to ensure the gear box is hard, wear-resistant, and free from tooth breakage; all gearboxes are equipped with ball bearings; right-angle gearboxes use Grason's arched gear structure, which has a greater torque transmission capability, twice to three times the load-bearing capacity of ordinary products, and is sturdy and durable; the gearboxes are filled with high-grade nano anti-wear lubricating grease.

5. Easy to Install: The reducer is designed with an internal threading installation standard, and is also equipped with stainless steel bushes for easy installation and thread durability; the output shaft bearing is embedded to eliminate the reducer's boss, allowing the housing to be directly installed next to the mounting surface without the need to worry about machining large holes on the mounting surface.

6. High Reliability: The electromagnetic system optimized by computers has higher motor operating efficiency and lower temperature rise; it uses H-level 180°C enameled wire and insulation materials with a large safety margin; it uses low-loss silicon steel plates and precision integrated stamping technology, with high precision and low loss.

Although the name suggests that the constant-speed motor cannot be adjusted, in fact, it is still possible to achieve the speed adjustment function through some common speed adjustment methods. Depending on different application scenarios and budgets, one needs to choose the speed adjustment method that suits them.

The wiring method for a constant-speed motor is actually very simple. A constant-speed motor mainly has three wires, one main wire, and the other two are for forward and reverse operations. The constant-speed motor is mainly connected to one capacitor. We connect the forward and reverse wires to the capacitor separately, and the other main wire is connected to one of the power lines, A. After plugging in the power, connect the power line B arbitrarily to the forward and reverse wires, and the motor will rotate forward and reverse.