Micro constant speed motor

25W Micro Constant Speed Motor

Product Overview

As a trusted manufacturer, we specialize in high-quality, reliable micro motor solutions tailored to diverse industry needs.

The 25W Micro Constant Speed Motor delivers exceptional power and precise speed control. Its compact, optimized design makes it perfect for space-constrained applications.

Built with advanced technology and precision craftsmanship, this motor ensures stability and top-tier performance. It boasts high energy efficiency, low noise, and reduced vibration, performing reliably under heavy loads or prolonged use.

Featuring adjustable speed control, the 25W Micro Constant Speed Motor offers flexibility to fine-tune speed as needed. This makes it ideal for precision-driven applications like medical devices, automation systems, and machinery.

Designed for durability, it resists corrosion and excels in longevity, thanks to premium materials and rigorous quality standards.

The 25W Micro Constant Speed Motor is a powerful, adaptable solution for any scenario—whether you need reliability or enhanced product performance, it’s the perfect fit.

For technical details or custom options, contact us today. Our team is here to provide expert support and solutions.

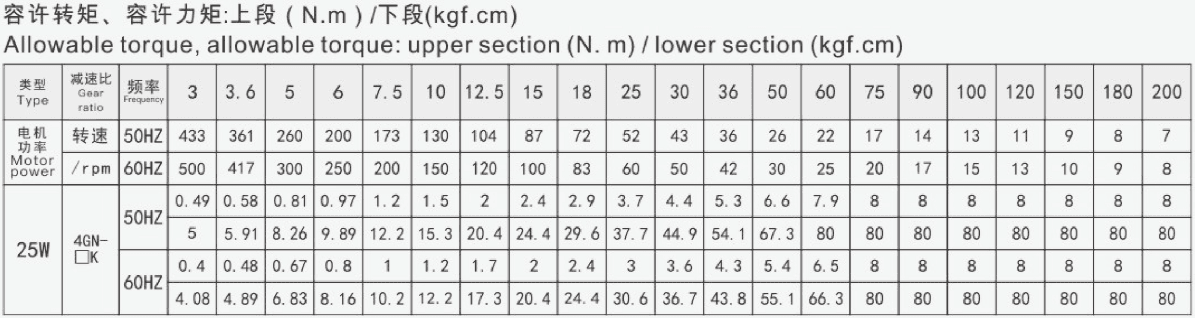

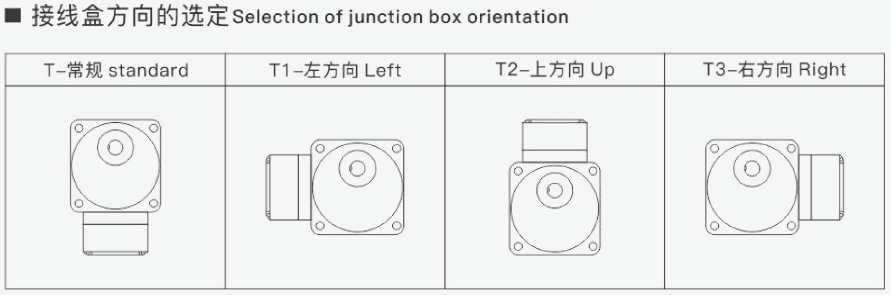

25W Micro Constant Speed Motor Model/Performance

*All safety specifications are cerfified by the model name on the nameplate of the motor

- The speed in the table is calculated by dividing the average speed of the motor by the deceleration ratio. The actual speed will vary with the load, ranging from 2 to 20%.

- The torque in the table is calcucated by the rated torque x deceleration ratio x transmission efficiency of the motor.

- The maximum allowable torque of the reducer is 8N.m.

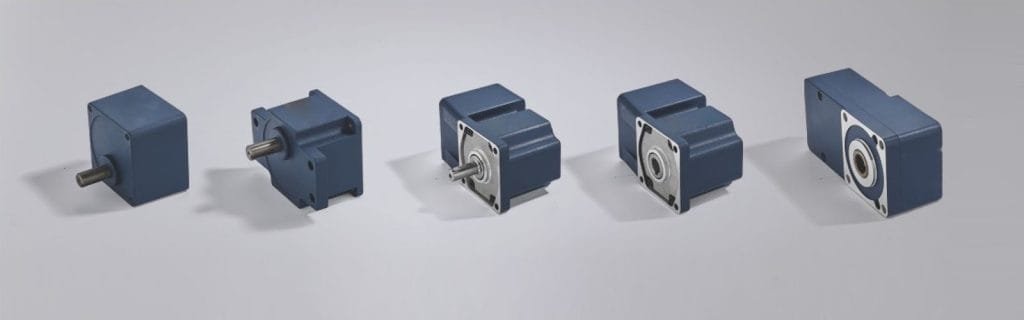

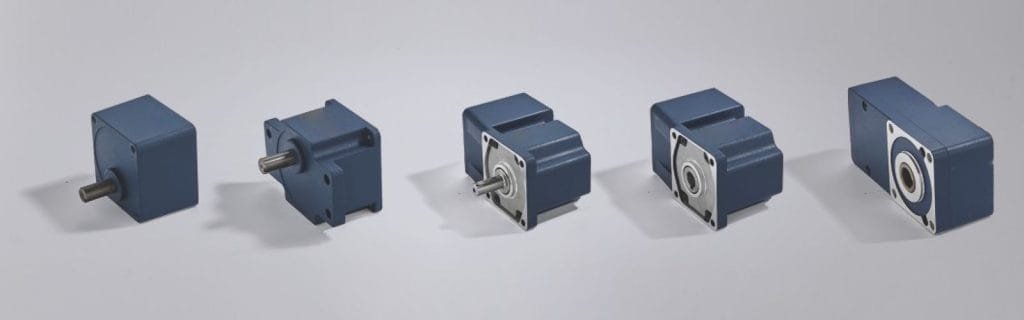

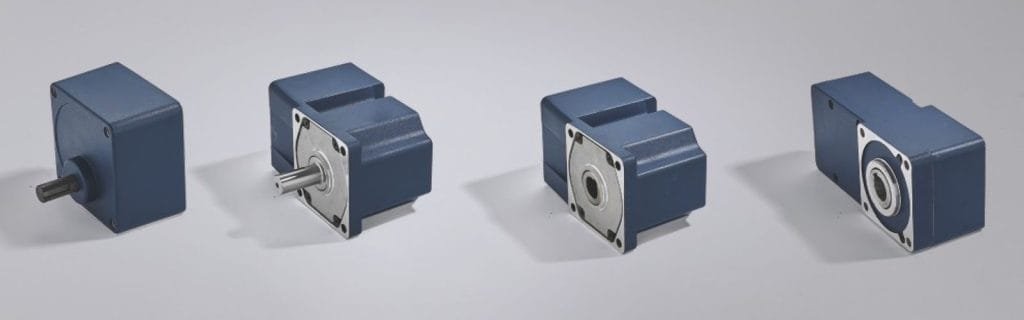

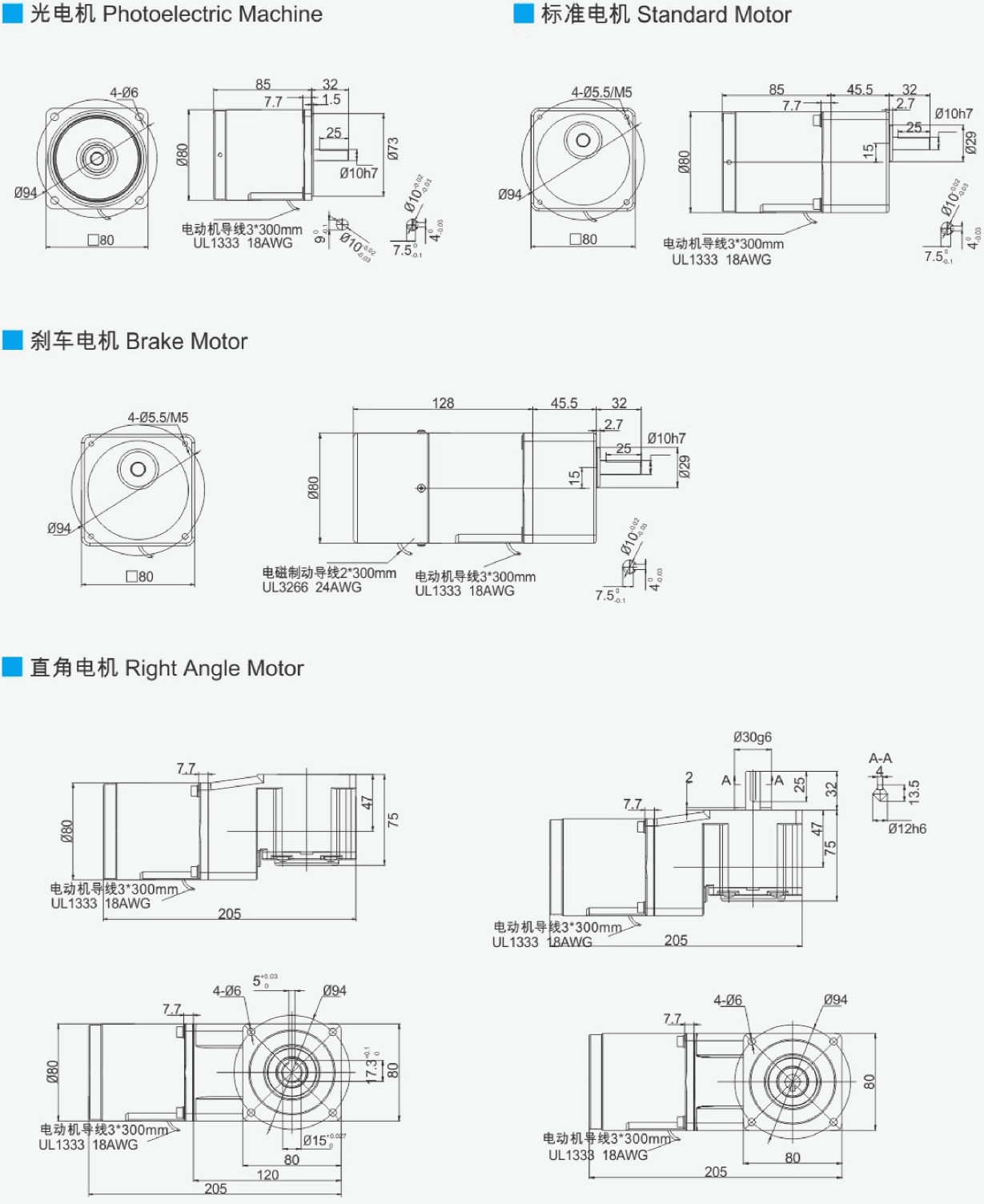

- Photoelectric Machine

- Standard Motor

- Brake Motor

- Right Angle Motor

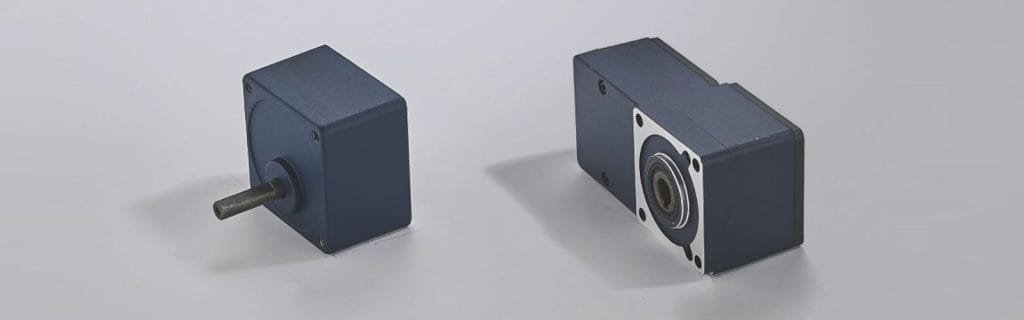

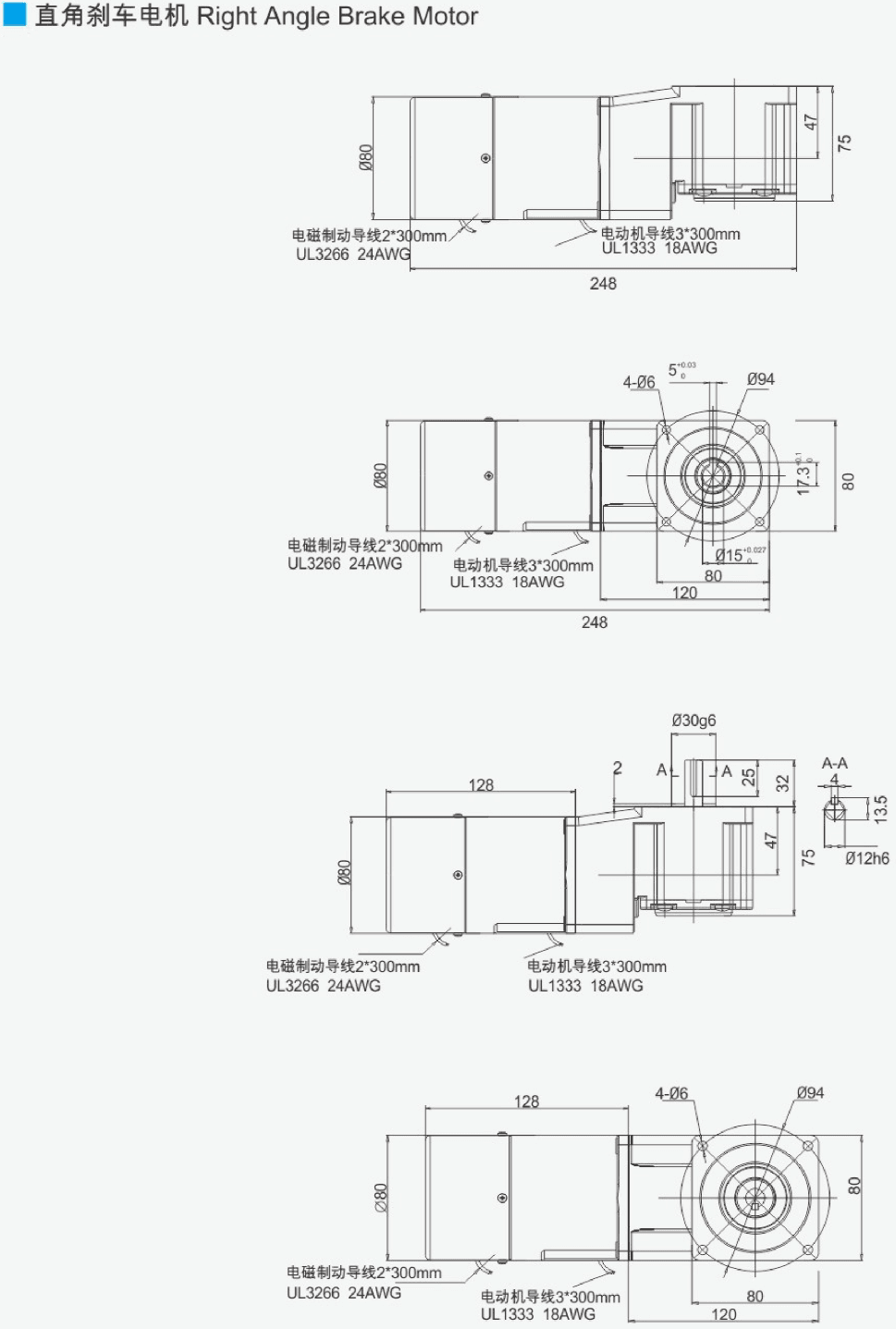

- 25W Miniature Constant Speed Motor – Dimensional Drawing of Right Angle Brake Motor

25W micro constant speed motor-L-type brake reducer, L-type reducer external dimension drawing

Miniature gear reduction motor series

Micro constant speed motor series models

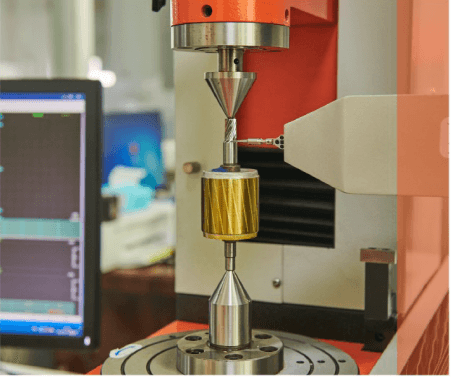

“High Quality, High Standards, Zero Defects”

Our company unites a team of seasoned professionals with over 20 years of expertise in production, technology, and sales. Composed of passionate and driven individuals, we share a common vision. We are dedicated to innovation across technology, manufacturing, management, and processes. With a full range of imported and domestic production and testing equipment, our integrated industrial assembly line ensures quality and efficiency. Supported by a strong sales network and comprehensive after-sales service, we strive to provide exceptional products and support to all our customers.

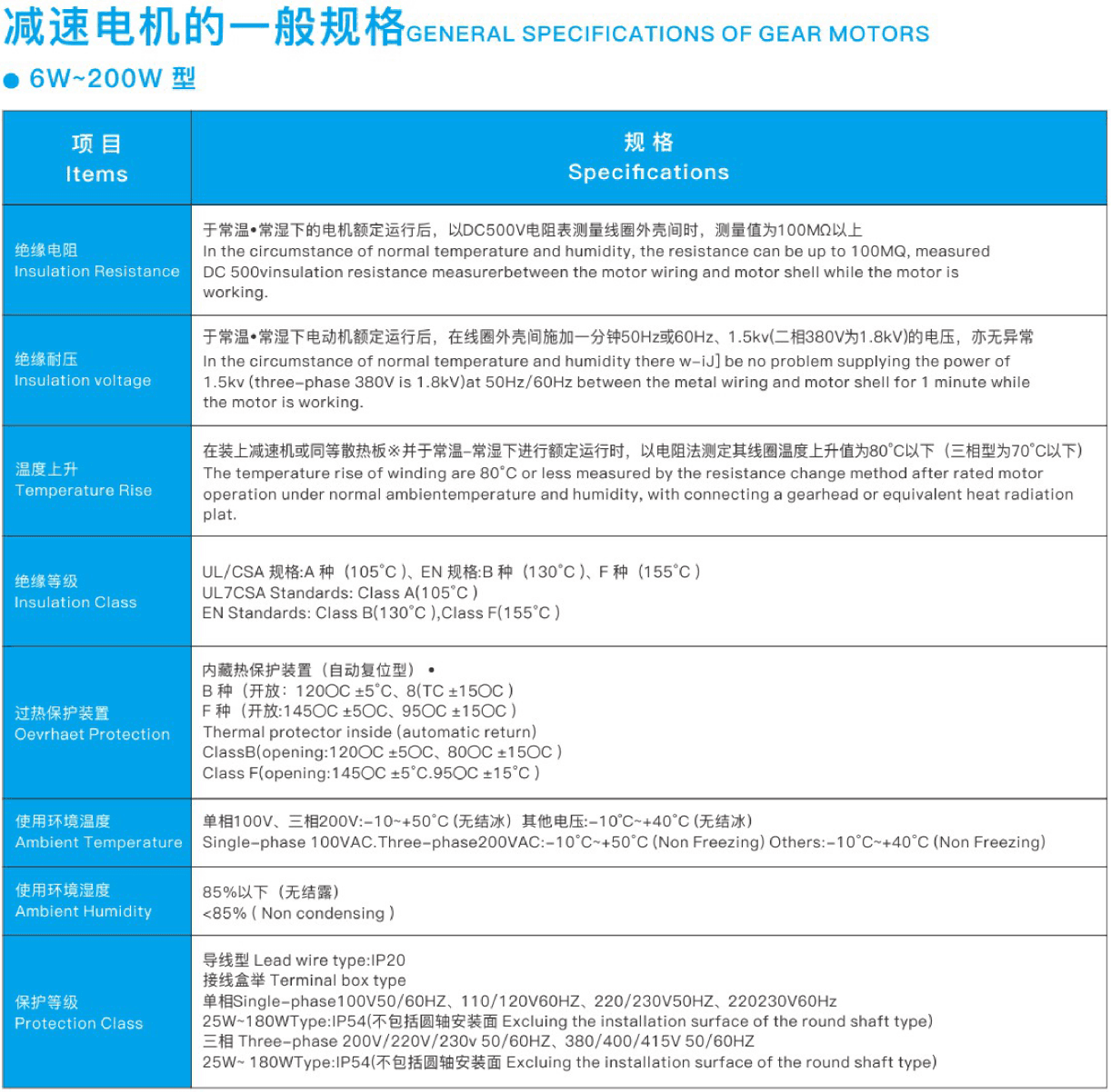

Reading method for specifications and models of micro constant speed motors

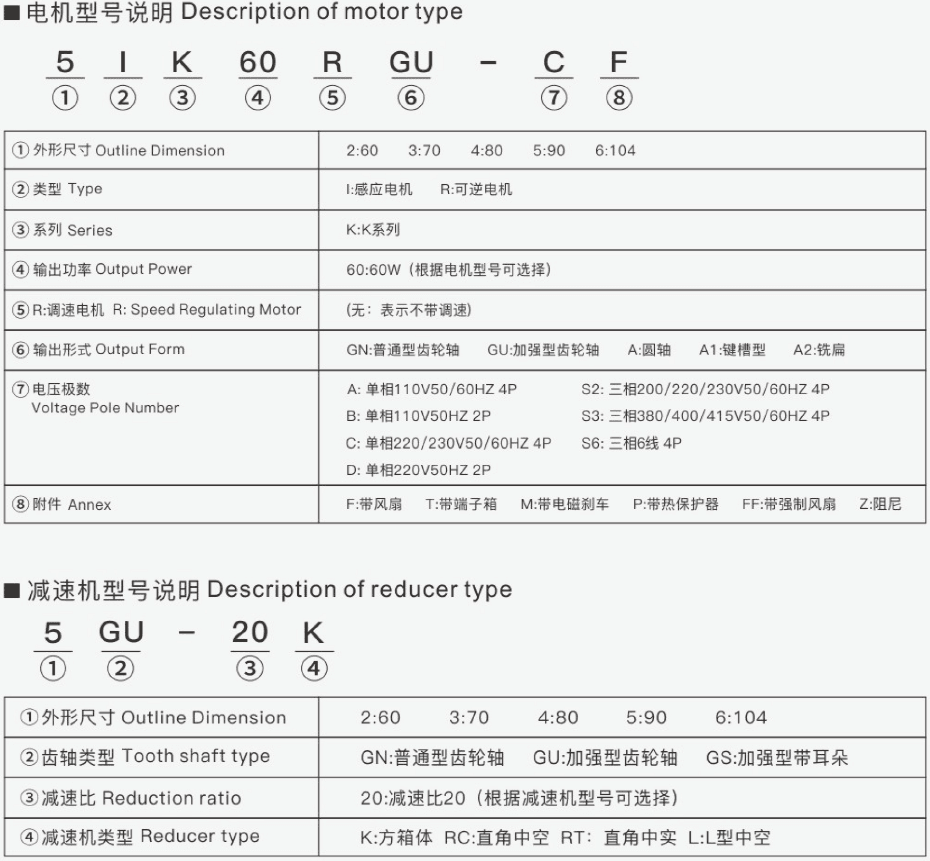

Selection of Junction Box Orientation

We Can Always Do Better

We focus on the details, enforcing strict quality control and robust process oversight to maintain high standards and prevent defects. Our comprehensive quality management system includes dedicated inspectors at every production stage, ensuring compliance with technical specifications. In the final inspection phase, skilled technicians conduct a full evaluation of each product’s appearance and performance, guaranteeing top-quality output before shipment.

Notes

Precautions for Installation and Use of Micro Constant Speed Motors

- General: Do not operate the gearbox or motor beyond the specifications on the nameplate or in the product catalog, as this may cause electric shock, injury, or damage to equipment. Avoid inserting fingers or objects into the gearbox or motor openings to prevent electric shock, injury, fire, or damage. Do not use a damaged gearbox or motor, which could result in injury or fire. Do not remove the nameplate. Unauthorized modifications by customers void the warranty, and our company assumes no liability.

- Handling: Exercise caution when moving the product, as dropping or tipping it poses significant risks.

- Installation: Keep flammable materials away from the gearbox and motor to prevent fire hazards. Ensure no objects block motor ventilation or cooling, as this could lead to burns or fire from overheating. Avoid touching the keyways of the gearbox or motor gears with bare hands to prevent injury. For applications like food machinery prone to oil leaks, attach an oil cup at the installation point to contain leaks and protect the product.

- Connection to Main Machinery: Equip rotating parts with safety covers to avoid injury. Confirm the rotation direction before connecting to other machinery, as incorrect rotation may cause injury or damage.

- Wiring: Do not touch terminals during insulation resistance testing to avoid electric shock.

- Operation: Connect to the power supply as per the wiring diagram or manual to prevent electric shock or fire. (For motors without a junction box, reinforce insulation at connection points.) Avoid Avoid excessive bending, stretching, or clamping of power cables or motor leads to reduce electric shock risks. Securely ground the grounding terminal to prevent electric shock. Use only the power supply specified on the nameplate to avoid motor burnout or fire.

- Daily Inspection and Maintenance: During operation, keep away from rotating parts (e.g., shafts) to avoid injury. In case of entanglement or injury, immediately switch off the power and respond promptly. During power outages, turn off the power switch to prevent injury or damage upon power restoration. Note: Motors with thermal protection will automatically shut off if overheated and restart once cooled, provided no damage has occurred.

- Inspection Upon Receipt: Confirm that the received product matches your order. Using the wrong product may damage the motor or equipment.

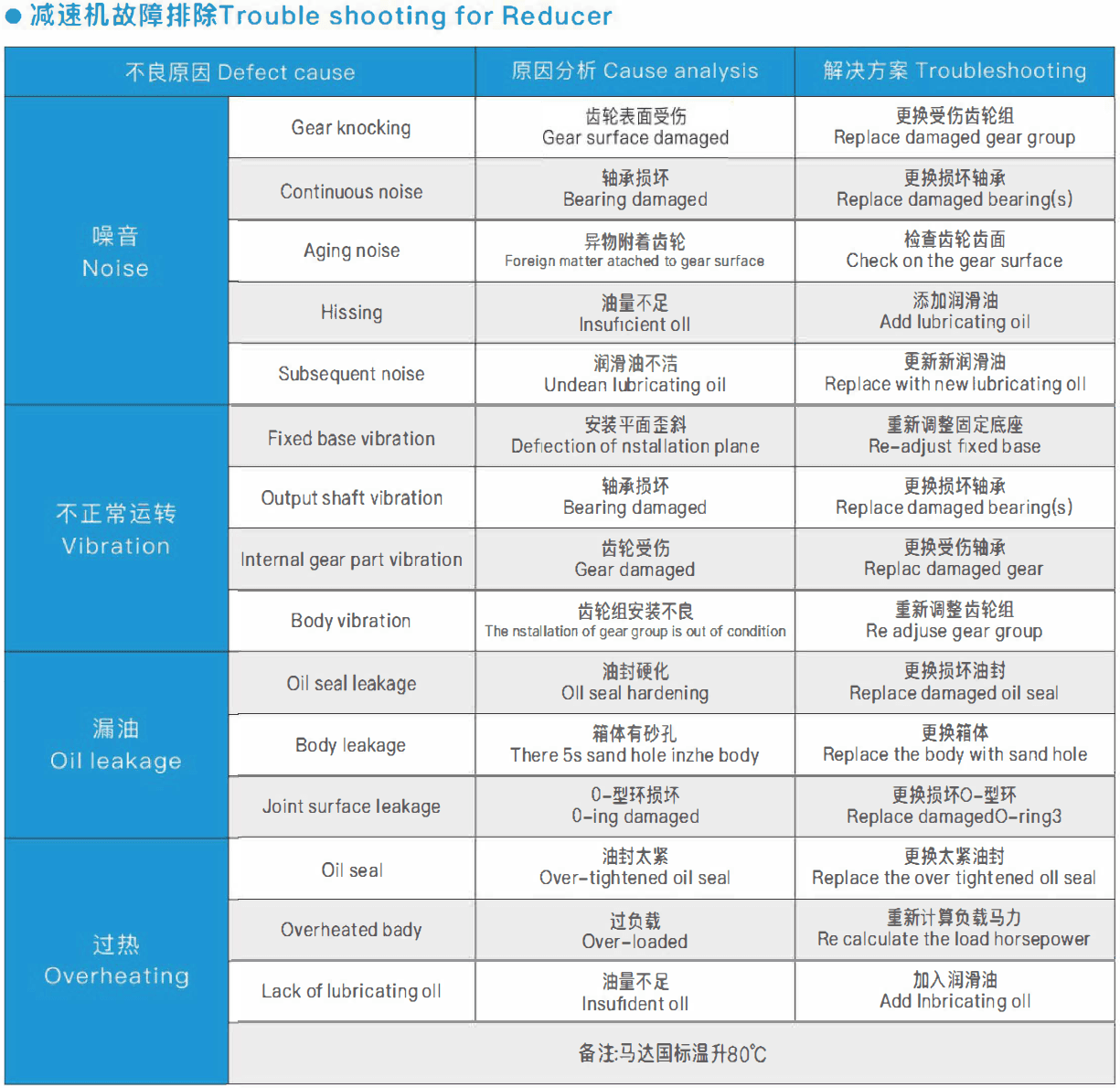

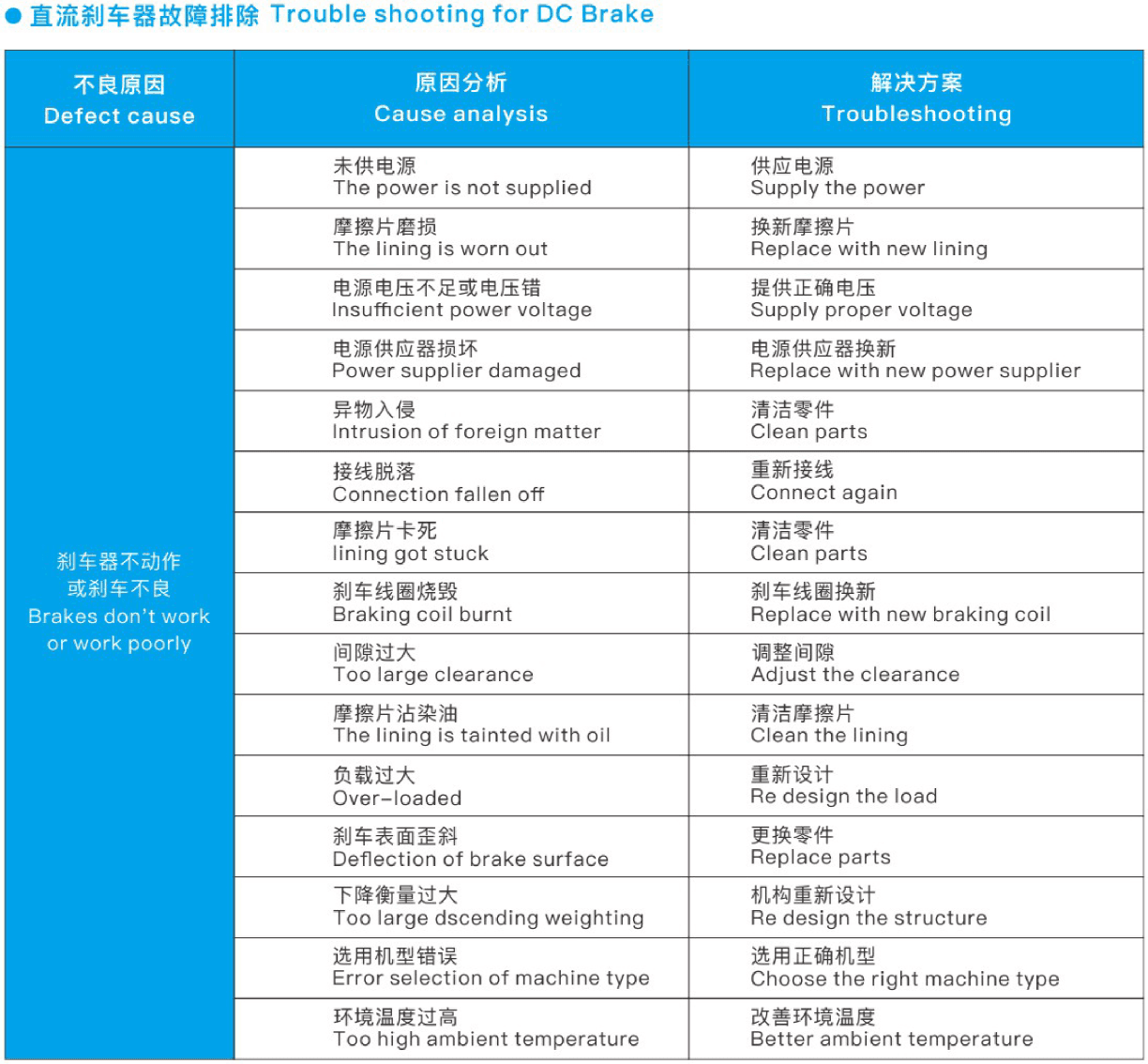

Trouble Shooting For Reducer

FAQs

Micro fixed speed motors usually use electronic control technology to regulate the motor speed by controlling the current or voltage. It usually consists of two parts: the motor body and the controller. The controller monitors the motor speed in real time through feedback signals and adjusts the current or voltage to achieve the desired speed control.

Choosing a suitable micro constant speed motor requires consideration of multiple factors, including the required speed range, load requirements, durability, and accuracy requirements. The size and power density of the motor should also be considered to ensure its adaptability to the space requirements and power consumption limitations of specific application scenarios.

Micro fixed speed motors have advantages such as small size, fast response, high efficiency, and high-precision control. They are suitable for various applications, can provide precise position and speed control, and achieve stable and reliable operation.

The high-precision control of micro constant speed motors is usually achieved through closed-loop feedback systems. Feedback sensors (such as encoders) are used to monitor the motor speed in real time and send feedback signals to the controller. The controller adjusts the current or voltage based on the feedback signal to achieve the desired speed of the motor.

Micro constant speed motors are widely used in automation equipment, robotics technology, medical devices, precision instruments, optical equipment, and other fields. They can be used to drive rotating platforms, precision positioning systems, precise motion control of medical devices, and more.

Usually, micro constant speed motors do not require frequent maintenance and upkeep. However, it is important to regularly check the operating status and temperature of the motor. Ensure good ventilation around the motor to prevent dust and particulate matter from entering. If any abnormal noise, vibration, or overheating issues are found, the motor should be immediately stopped and checked.

Micro constant speed motors and variable speed motors are two different types of electric motors, which differ in their working principles and functions. Here are some key characteristics that distinguish between constant speed motors and variable speed motors:

- Working principle: A constant speed motor will operate at a constant speed, regardless of changes in load. Variable speed electric motors can adjust their output speed as needed to meet different load requirements.

- Control method: Constant speed motors usually use open-loop control, which means that a specific voltage and frequency are given to maintain a constant speed. Variable speed motors typically use closed-loop control to adjust output speed through sensor feedback.

- Application areas: Constant speed motors are suitable for applications that require high speed and minimal load changes, such as clocks, instruments, and equipment. Variable speed electric motors are suitable for applications that require real-time speed adjustment based on load changes, such as mechanical transmission systems, speed controllers, etc.

Constant speed motors and variable speed motors are two different types of motors that differ in speed control. Here is the difference between a fixed speed motor and a variable speed motor:

- Speed control: The speed of the constant speed motor is fixed and cannot be adjusted, it always runs at a constant speed. The speed regulating motor has the ability to adjust the speed and can change the output speed at any time according to demand.

- Control method: Constant speed motors usually use open-loop control, which means that a specific voltage and frequency are given to maintain a constant speed. Adjustable speed motors typically use closed-loop control, adjusting output speed through sensor feedback to achieve precise speed control.

- Application scope: Fixed speed motors are suitable for applications that require high speed and small load changes, such as clocks, instruments, and equipment. Adjustable speed motors are suitable for applications that require real-time speed adjustment according to load requirements, such as industrial production lines, fans, pumps, etc.

Safe and Beautiful: Miniature junction box protection, IP54 level, makes wiring and replacement more convenient, safer, and more beautiful, enabling your product to better meet safety standards.

2. Rich range of models: With strong financial and technological capabilities, we offer rack bases ranging from 60-100mm and power outputs from 6W to 200W.

3. Ultra low noise: High precision hobbing machines and AAA high-grade rolling cutters are used to process high-precision helical gears. The four corners of the four box body adopt a high rigidity structure in the form of double columns, which is sturdy and does not deform even under high load conditions, and has low vibration.

4. Ultra long lifespan: The gear material is made of high-grade alloy steel containing molybdenum and undergoes special heat treatment to ensure that the gearbox is hard, wear-resistant, and has no teeth; All gearboxes are equipped with ball bearings; The right angle gearbox adopts a Grayson arc-shaped tooth structure, which has a large transmission torque and a load-bearing capacity 2 to 3 times that of ordinary products, making it sturdy and durable; The gearbox is filled with advanced nano anti-wear grease.

5. Easy to install: The gearbox adopts internal thread installation standard and is equipped with stainless steel screw sleeves, which are easy to install and the threads are not easily damaged; Embedding the output shaft bearing to eliminate the gearbox boss, the axle box can be directly installed next to the installation surface without worrying about machining large holes on the installation surface.

6. High reliability: The electromagnetic system optimized by the computer has high motor operating efficiency and low temperature rise; Using H-grade 180 ℃ enameled wire and insulation material, with a large safety margin; Using low loss silicon steel plates and precision integrated stamping technology, high precision and low loss.

Although the name implies that a fixed speed motor cannot be adjusted, in reality, it can still achieve speed control function through some commonly used speed control methods. For different application scenarios and budgets, it is necessary to choose a suitable speed control method.