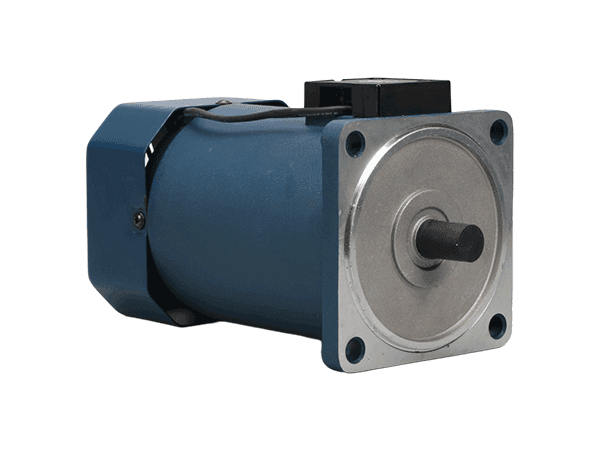

YB series electromagnetic brake motor

YB series electromagnetic brake motor Overview

HM Motor has always adhered to the philosophy of “convenience, innovation, and excellence,” delivering high-quality, reliable, and intelligent products to customers. The YB series motor, equipped with an electromagnetic brake, represents an innovative achievement by HM Motor. When handling vertical loads or requiring rapid stops, the electromagnetic brake quickly locks the motor, ensuring the absolute safety of the mechanical structure. Even during power outages or interruptions, the fail-safe electromagnetic brake guarantees the safe operation of the mechanical system.

For user convenience, the YB series motor can only be speed-adjusted via a frequency inverter. However, for those needing speed control through a governor, HM Motor also offers the YF series speed-adjustable electromagnetic brake motor as an alternative option.

Moreover, HM Motor maintains stringent quality control, utilizing premium raw materials and cutting-edge manufacturing techniques. Every product undergoes rigorous testing and inspection. Additionally, we provide comprehensive after-sales service, offering technical support and solutions to our customers.

Available Power Options for the YB Series Electromagnetic Brake Motor:

- 6W (60×60mm)

- 15W (70×70mm)

- 25W (80×80mm)

- 40W (90×90mm)

- 60W (90×90mm)

- 90W (90×90mm)

- 120W (90×90mm)

- 200W (100×100mm)

Characteristics of YB series electromagnetic brake motor

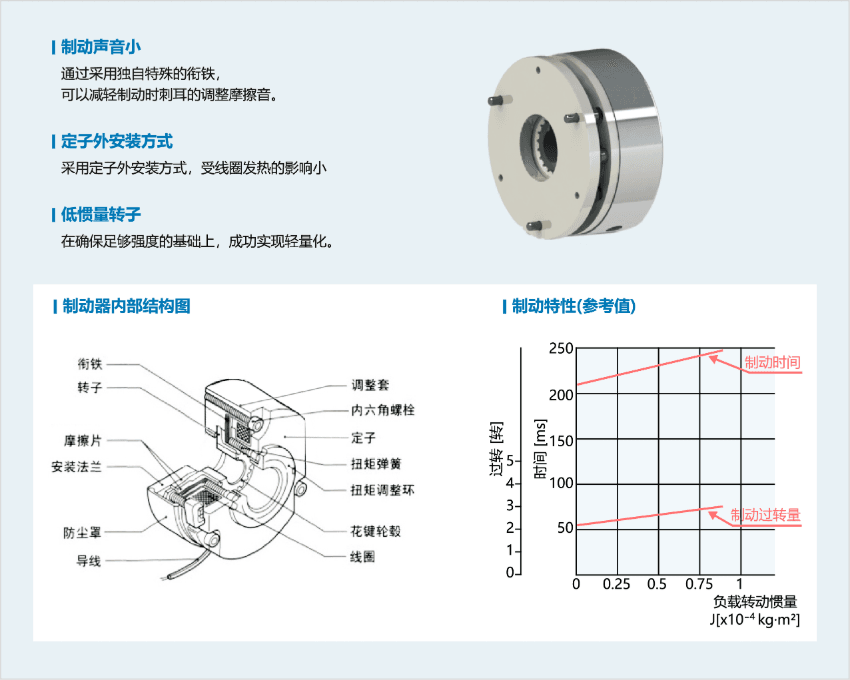

Safe and Reliable: The electromagnetic brake is designed for stability and rapid response, with a braking response time of less than 200ms and a total braking work lifespan of up to 4.6×10⁸ joules, ensuring user safety during operation.

Simple and Ingenious Design: When the brake loses power, the armature is released, and the spring resets it to press against the friction disc, locking the motor shaft as the friction disc grips it, holding the load in place. This straightforward and comprehensible structure is easy to maintain and service.

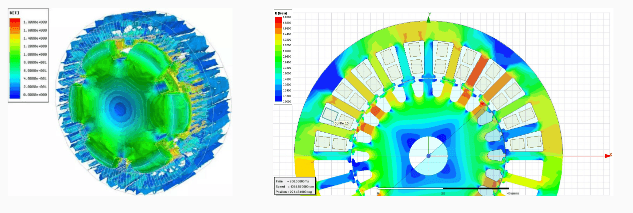

The electromagnetic system of the motor is optimized through ANSYS finite element analysis and simulation, ensuring stability, reliability, higher efficiency, and lower temperature rise.

Powerful and Efficient Performance: During rated operation, the winding temperature rise, measured using the resistance method, is kept below 70K, enhancing reliability. The motor noise level is ≤50dB, ensuring user comfort during operation. With a maximum efficiency of 74.1%, the motor delivers high-performance operation.

The motor can operate smoothly and reliably for extended periods under harsh conditions such as high temperatures, low temperatures, and high altitudes, ensuring its dependability and stability.

Designed for Demanding Conditions with the Following Adaptability Features:

- Suitable for a minimum ambient temperature of -10°C, ensuring effective performance in low-temperature environments;

- Suitable for altitudes up to 2000m, enabling reliable use in high-altitude settings;

- Suitable for a maximum ambient temperature of 45°C, supporting operation in high-temperature conditions;

- Suitable for environments with a maximum humidity of 90%, ensuring reliability in humid conditions;

- Suitable for a voltage deviation of ±10%, maintaining stability during voltage fluctuations.

The motor’s waterproof protection structure meets IP54 standards, ensuring safety and reliability when operating in wet environments.

- Multiple voltage options available

- Choice of various gear ratios and power levels

- Supports multiple assembly configurations, including two-stage reduction

- Compatible with a wide range of gearboxes

- Gear ratio range from 1:3 to 1:1800

- Options include single-phase 110V, single-phase 220V, three-phase 220V, three-phase 380V, and other global voltage standards

- Customizable to meet unique voltage requirements

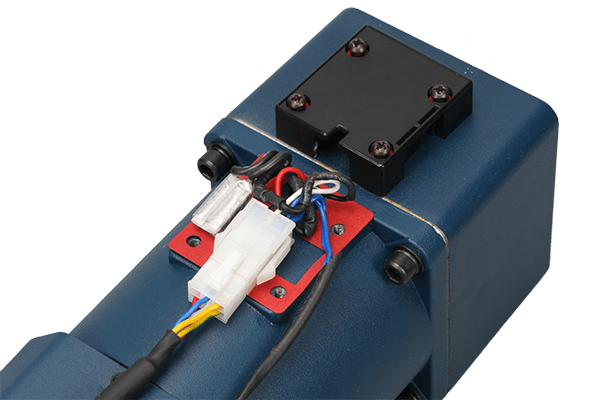

- Patented external temperature control junction box

- Terminal wiring design for easy maintenance and connection

- External design significantly extends the motor’s service life

- Stable operation ensures uninterrupted production lines

- Multiple international certifications, including China Compulsory Certification (CCC)

- All models comply with various safety standards

- Certified under the China Compulsory Certification (CCC) system

- Compliant with the CE marking (Low Voltage Directive)

- Meets RoHS Directive, free of six hazardous substances including lead and cadmium

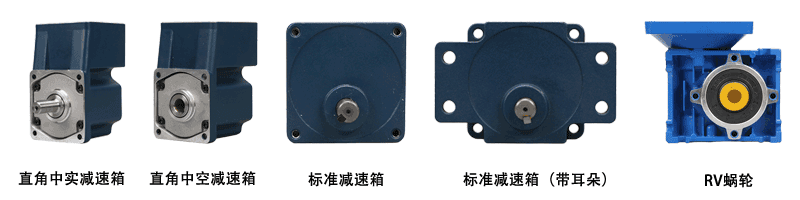

YB series electromagnetic brake motor - common combinations

Gearbox - "Increase torque, increase output"

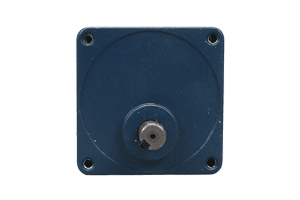

Standard gearbox

Speed ratio: 1:3~1:500

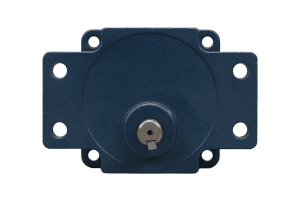

Standard gearbox (with ears)

Speed ratio: 1:3~1:500

Speed ratio: 1:5~1:80

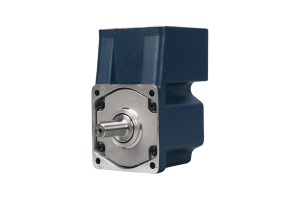

Right angle solid reduction gearbox

Speed ratio: 1:3~1:180

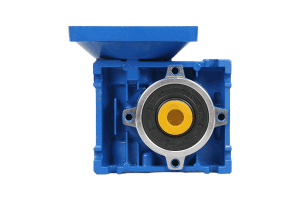

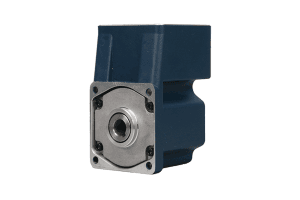

Right angled hollow gearbox

Speed ratio: 1:3~1:180

Controller - "Flexible Control, Diverse Output"

YB series electromagnetic brake motor - FAQs

U. V and W have a broken wire, causing a phase loss and preventing them from starting.

Y-shaped connection method.

No, you can use a frequency converter to adjust the speed.

H (horizontal), V (vertical), RT (right angle solid), RC (right angle hollow)

There are three-phase 220V and three-phase 380V.

- Controlled by switches and contactors

- Controlled by frequency converter

Can be matched with a frequency converter to achieve multi-stage speed control.

Considering cost, a three-phase 220V motor is preferred. Considering three-phase balance, a three-phase 380V motor is preferred.

There are three-phase input types available.

Can be paired with a frequency converter for speed regulation.

Select and match according to the same machine base number.

Yes.

Suitable for 90 ° installation scenarios.