YT Series Speed Regulating Motor

YT Series Speed Regulating Motor Overview

HM Motor upholds the philosophy of “simplicity in use, innovation for excellence,” delivering high-quality, reliable products to customers.

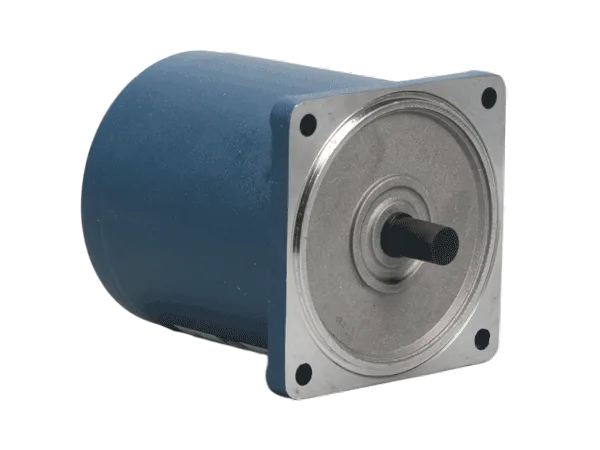

The YT series speed-adjustable motor is equipped with a speed feedback tachometer, making it suitable for general applications requiring speed control. Its standout feature is “simplicity and ease of use,” while also offering a wide speed adjustment range and various flexible functions.

The speed-adjustable motor requires the use of a corresponding speed controller, including our company’s US series, M digital display series, and F book-style series speed controllers.

Characteristics of YT series speed regulating motor

Accurate Closed-Loop Speed Control:

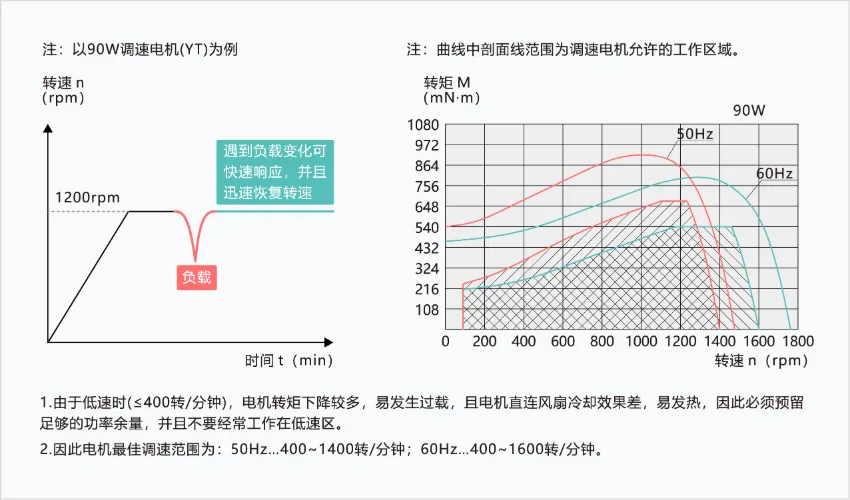

- Utilizes a speed feedback tachometer to achieve precise closed-loop speed control, enabling flexible speed adjustment within the range of 90~1400 r/min at 50Hz frequency.

- Offers multiple convenient and reliable functions, including gradual acceleration, gradual deceleration, rapid stopping, and 0~10V analog control.

Proven Reliability Through Repeated Validation:

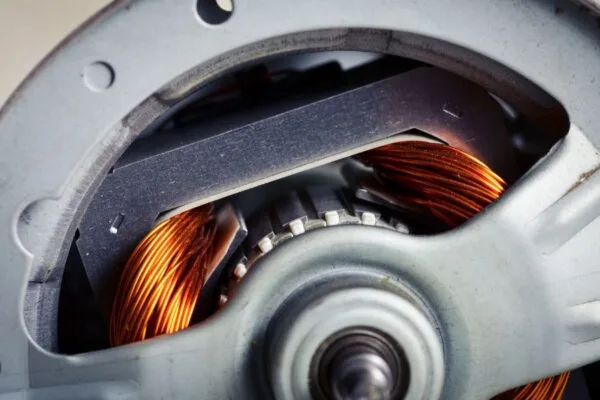

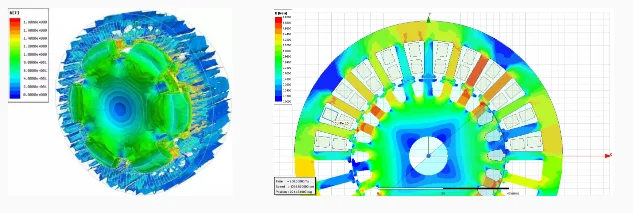

- Features an electromagnetic system optimized through ANSYS finite element analysis and motor simulation, resulting in higher efficiency and lower temperature rise.

- During rated operation, the winding temperature rise, measured using the resistance method, remains below 70K.

- Motor noise is ≤50dB, with a maximum efficiency of 74.1%.

Durability for Various Operating Conditions:

- Capable of stable, long-term operation even under harsh conditions such as high temperatures, low temperatures, and high altitudes.

- Suitable for demanding usage scenarios, including:

- Usable at a minimum ambient temperature of -10°C.

- Usable at altitudes up to 2000m.

- Usable at a maximum ambient temperature of 45°C.

- Usable at a maximum ambient humidity of 90%.

- Usable with a voltage deviation tolerance of 10%.

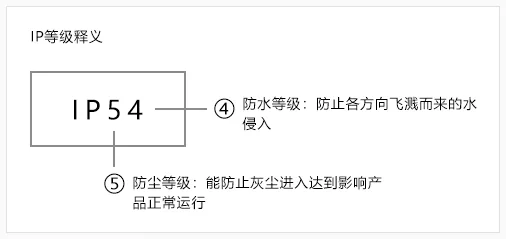

- The motor’s waterproof protection structure achieves an IP54 rating.

Flexibility to Meet Diverse Needs:

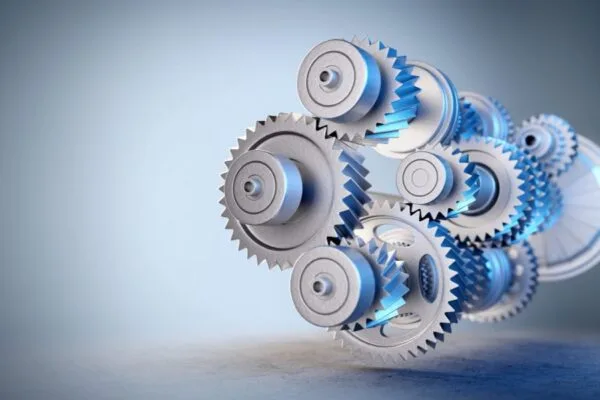

- Allows selection from various voltage levels, gear ratios, and power options based on requirements.

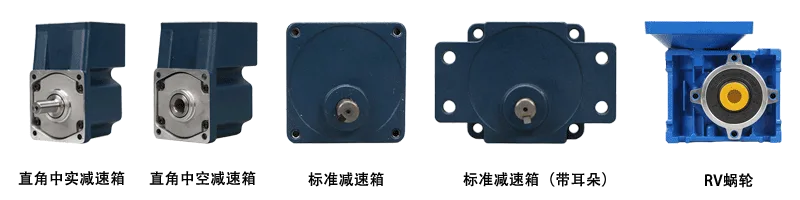

- Offers extremely versatile gearbox compatibility, with a gear ratio range from 1:3 to 1:1800, supporting two-stage reduction, right-angle solid shaft, right-angle hollow shaft, round shaft, crankshaft, and multiple other assembly configurations.

- Compatible with global voltages, providing options of single-phase 110V, single-phase 220V, three-phase 220V, and three-phase 380V, with the ability to customize unique voltage requirements upon request.

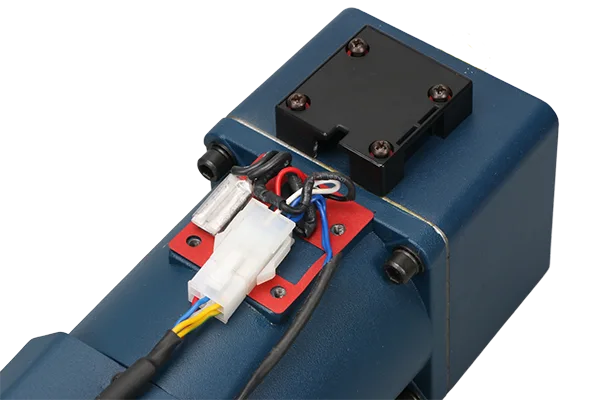

External Temperature Control Junction Box with Patented Design:

- Equipped on all models with a patented design.

- Utilizes terminal connections for wiring, requiring only a single connection, significantly enhancing the convenience of maintenance and installation.

- This design greatly extends the motor’s service life.

- The external temperature control junction box also ensures uninterrupted production line operation.

Certified to Multiple International Standards:

- Obtained various international certifications and complies with multiple international safety standards.

- All models meet a range of safety specifications.

- Certified under China’s Compulsory Product Certification System (CCC System).

- Compliant with CE Marking (Low Voltage Directive).

- Conforms to the RoHS Directive, free of six chemical substances including lead and cadmium.

YT series speed regulating motor - common combinations

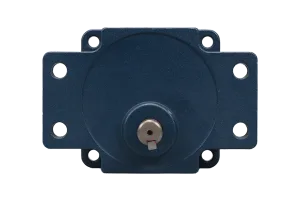

Gearbox - "Increase torque, increase output"

Standard gearbox

Speed ratio: 1:3~1:500

Standard gearbox (with ears)

Speed ratio: 1:3~1:500

Speed ratio: 1:5~1:80

Right angle solid reduction gearbox

Speed ratio: 1:3~1:180

Right angled hollow gearbox

Speed ratio: 1:3~1:180

Controller - "Flexible Control, Diverse Output"

US series motor speed controller

Motor speed regulation positive and negative control

Digital M series speed controller

Utilizing closed-loop control to achieve high reliability

Embedded book style F-series speed controller

Supports standard Modbus RTU 03 and 06 function codes

YT系列调速电机-常见问题解答

The speed controller is a closed-loop control system, and a single speed controller cannot control multiple speed regulating motors.

Environmental temperature: -10 ℃ to+45 ℃ (no icing), environmental humidity: below 85% (no condensation)

Check the motor wiring and whether the capacitor is installed correctly.

The capacitor is connected to U2 and Z2 terminals.

1. The motor did not run before the Er-1 fault alarm: the connection line between the motor and the governor was abnormal; If the motor is overloaded or stuck, the motor power should be increased or the reduction ratio should be increased.

2. Before the Er-1 fault alarm, the motor runs for 10 seconds: the connection line between the governor and motors S1 and S2 is broken or not connected

3. The motor is running, but after running for a period of time, Er-1 fault alarm: the load is too high, the motor power is too low, and the motor power should be increased or the reduction ratio should be increased.

The governor/driver has no fault output signal, and the DK series governor/driver can be selected to read fault information and codes through RS-485 communication.

The rotation mode of the governor/driver menu F-04 is set to 1: allowing forward and reverse rotation.

Long press the mode key until C100 is displayed, adjust to C123, and press ENTER to enter the menu.