Products

2200W permanent magnet variable frequency synchronous motor

Parameters of 2200W permanent magnet variable frequency synchronous motor

- Rated Voltage: Three-phase 220V, Three-phase 380V

- Maximum Output Power: 2200W

- Frequency Adjustment Range: 2-75Hz

- Speed Reduction Range: 50-2000 r/min

- Rated Current: Three-phase 220V 9.5A, Three-phase 380V 8.7A

- Starting Torque: Three-phase 220V 23.5 N·m, Three-phase 380V 23.5 N·m

- 50Hz Torque: Three-phase 220V 15.6 N·m, Three-phase 380V 14 N·m

- Protection Level: IP44

- Duty Type: S1

- Drive Mode: Variable Frequency Drive

- Energy Efficiency Level: Level 1 Energy Efficiency

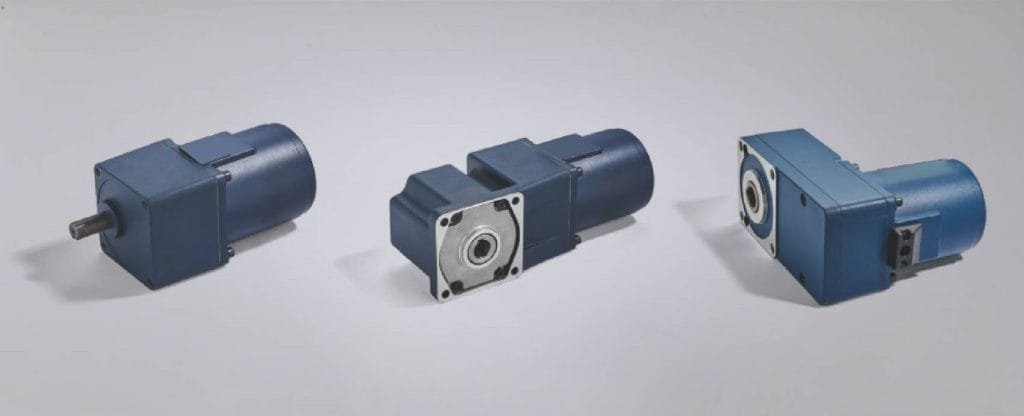

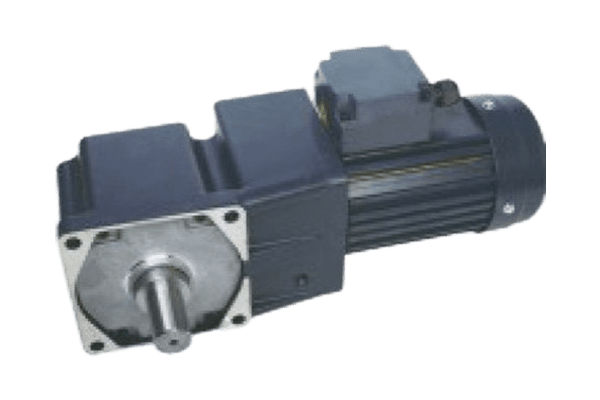

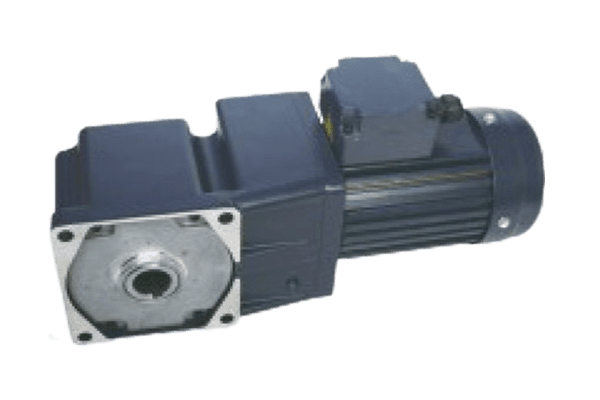

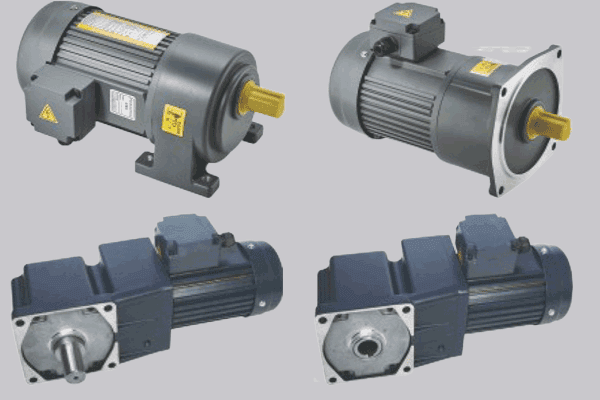

Product portfolio

Reduction ratio: 1:3-60

Model: YH□-2200-□-S

Reduction ratio: 1:3-60

Model: YV□-2200-□-S

Reduction ratio: 1:5-36

Model: YRT□-2200-□-S

Reduction ratio: 1:5-36

Model: YRC□-2200-□-S

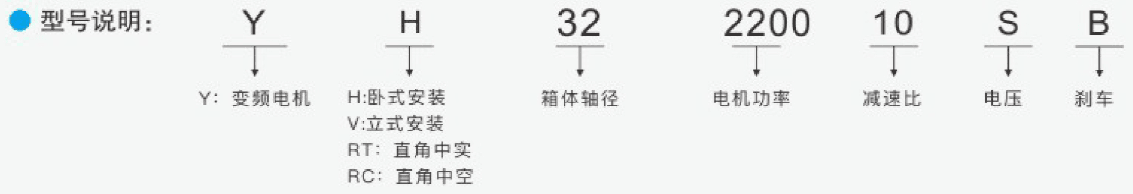

Model Description

Characteristics of Permanent Magnet Variable Frequency Synchronous Motor

The 2200W Permanent Magnet Variable Frequency Synchronous Motor offers the following advantages and features:

- Permanent Magnet Synchronous Technology: This motor employs permanent magnet synchronous technology, delivering higher efficiency and power factor compared to traditional asynchronous motors, resulting in superior performance. This maximizes energy utilization, thereby reducing energy costs.

- Variable Frequency Control: Through variable frequency control, the motor achieves precise regulation of speed and torque, allowing flexible adjustments to rotational speed and output power based on specific needs. It is ideal for applications requiring high precision and high-speed control. Additionally, it provides enhanced start and stop performance, further improving operational efficiency.

- Intelligent Management: The motor supports intelligent management and monitoring, enabling real-time tracking of operating conditions and performance metrics. Using intelligent algorithms, it automatically adjusts parameters and control strategies to optimize performance, minimizing losses and failures due to improper settings or operational errors.

- Stability: With the integration of permanent magnet synchronous technology and variable frequency control, this motor offers improved control precision and stability. It maintains consistent performance under high loads, low loads, and during acceleration, providing customers with more reliable products and services.

- Durability: Constructed with advanced materials and manufacturing techniques, the motor boasts enhanced durability and wear resistance, ensuring a longer service life and lower maintenance costs. It also includes multiple protective features such as overload protection, short-circuit protection, and overheat protection, ensuring safe operation for users.

Application of Permanent Magnet Variable Frequency Synchronous Motor

Today, permanent magnet variable frequency synchronous motors are widely used across various industries and applications. Their primary advantages include improved energy efficiency, enhanced production efficiency, reduced machine failure rates, lower maintenance costs, and increased precision and stability. Below are some key industries and scenarios where they are applied:

- Packaging Industry: Permanent magnet variable frequency synchronous motors are utilized in a variety of packaging equipment, such as those for food, pharmaceuticals, beverages, and cosmetics. Their high efficiency and exceptional precision enable packaging equipment to produce more products per hour, while reducing energy consumption, waste, and maintenance costs.

- Pharmaceutical Industry: In pharmaceutical machinery, permanent magnet synchronous motors are widely adopted. Their precision and stability ensure better quality control and production efficiency in drug packaging and manufacturing processes. Examples include drug production machinery and pharmaceutical conveyor belts.

- Mechanical Manufacturing Industry: Permanent magnet variable frequency synchronous motors are employed in mechanical manufacturing equipment requiring high precision and speed, such as textile machinery, vertical machining centers, and CNC machine tools.

- Automation Equipment Industry: In automation equipment, these motors fully leverage their greatest strengths. With high efficiency and superior precision, they are applied in rolling bearings, robotic arms, industrial robots, cutting machines, conveyors, and other automated systems, enhancing energy-saving benefits and production efficiency.

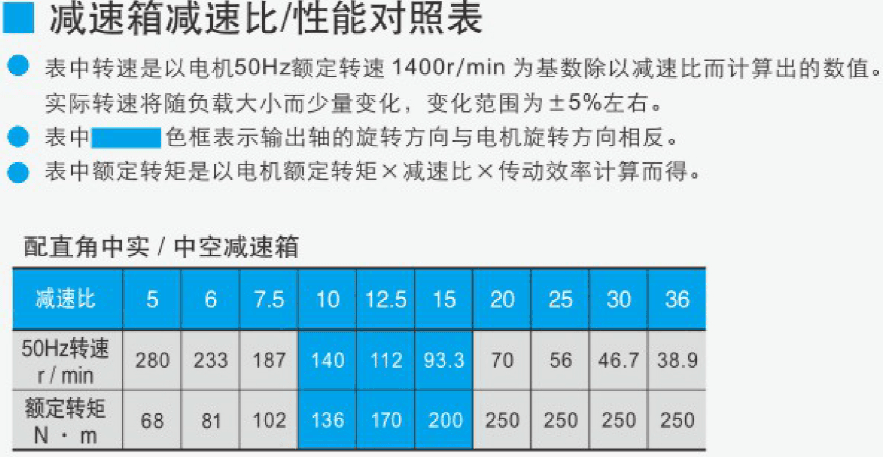

Comparison Table of Reduction Ratio and Performance of 2200W Permanent Magnet Variable Frequency Synchronous Motor Gearbox

Outline dimension drawing of 2200W permanent magnet variable frequency synchronous motor

Advantages of choosing HM Motor

Our company offers highly competitive pricing in the market. We leverage advanced production processes and a robust production management system, utilizing mass production and centralized raw material procurement to reduce manufacturing costs. We prioritize our customers’ interests above all, maintaining production costs within a reasonable range without compromising the quality or performance of our products. As a result, compared to similar products in the market, our pricing demonstrates a strong competitive edge.

Product advantages:

- High Efficiency and Energy Saving: Utilizing permanent magnet synchronous technology, the motor achieves high efficiency and low energy consumption, meeting the national Level 1 energy efficiency standard.

- Wide Voltage Range: The motor operates effectively across a broad range of supply voltages, offering strong adaptability.

- Precise Control: Employing variable frequency speed regulation technology, it provides high control precision to meet the demands of various applications.

- Low Vibration and Low Noise: The motor runs smoothly with minimal noise, making it suitable for environments with stringent noise requirements.

Service advantages:

- Pre-Sales Service: The company offers comprehensive pre-sales support, assisting customers in carefully selecting the products best suited to their needs.

- After-Sales Service: The company has a professional after-sales team providing all-around services, including repairs, maintenance, and upgrades.

- Technical Support: The company maintains a dedicated technical support team, available to provide guidance and consultation at any time, ensuring customers can use the motors with complete peace of mind.

- Quality Assurance: The company’s products come with quality guarantees, backed by a commitment to quality and a robust assurance system, allowing customers to purchase and use our products with confidence.