Products

750W permanent magnet variable frequency synchronous motor

Parameters of 750W permanent magnet variable frequency synchronous motor

- Rated Voltage: Three-phase 220V, Three-phase 380V

- Maximum Output Power: 750W

- Frequency Adjustment Range: 2-75Hz

- Speed Reduction Range: 50-2000 r/min

- Rated Current: Three-phase 220V 3.4A, Three-phase 380V 2.0A

- Starting Torque: Three-phase 220V 11.9 N·m, Three-phase 380V 11.9 N·m

- 50Hz Torque: Three-phase 220V 5.4 N·m, Three-phase 380V 5.4 N·m

- Protection Level: IP44

- Duty Type: S1

- Drive Mode: Variable Frequency Drive

- Energy Efficiency Level: Level 1 Energy Efficiency

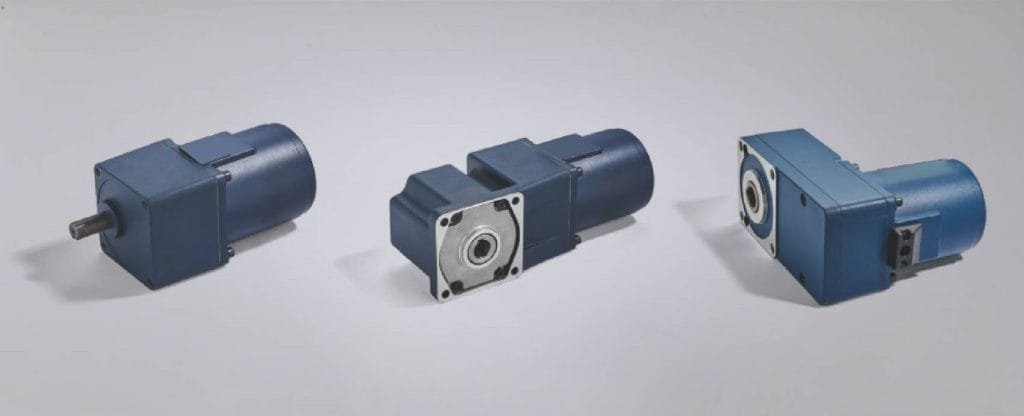

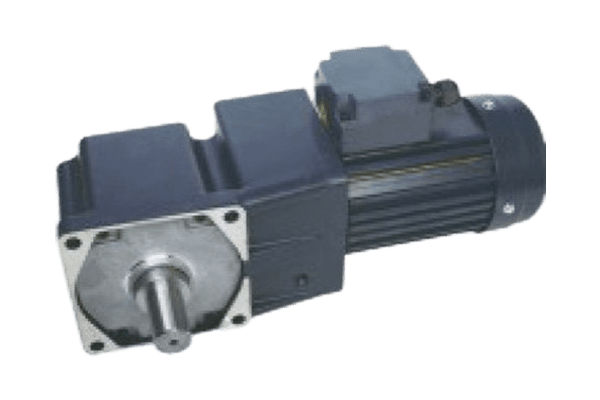

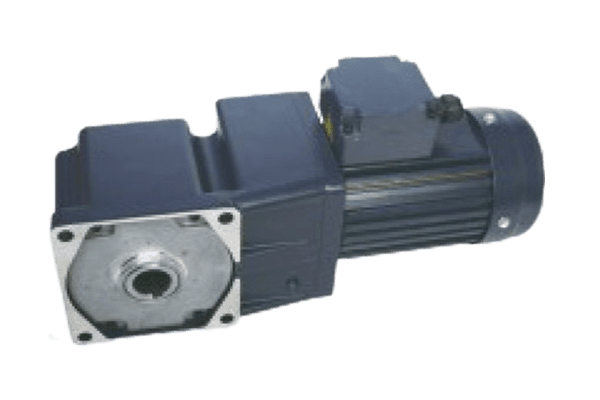

Product portfolio

Reduction ratio: 1:3-140

Model: YH□-750-□-S

Reduction ratio: 1:3-140

Model: YV□-750-□-S

Reduction ratio: 1:5-75

Model: YRT□-750-□-S

Reduction ratio: 1:5-75

Model: YRC□-750-□-S

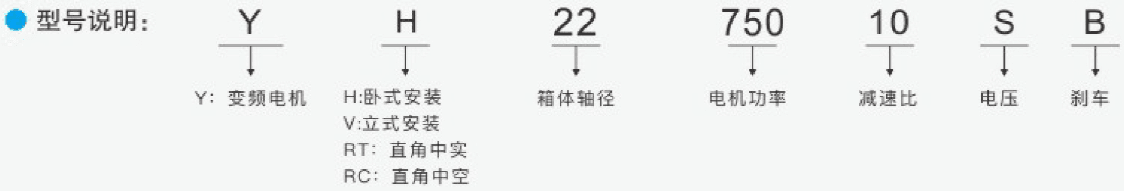

Model Description

Characteristics of Permanent Magnet Variable Frequency Synchronous Motor

The HM Motor 750W Permanent Magnet Variable Frequency Synchronous Motor features the following characteristics:

- Permanent Magnet Synchronous Technology: Utilizing permanent magnet synchronous technology, it achieves higher efficiency and lower energy consumption. Compared to traditional asynchronous motors, it offers greater torque and power factor, effectively enhancing equipment productivity and quality.

- Variable Frequency Control: Employing variable frequency control technology, the motor allows real-time adjustment of output power and speed, making it adaptable to various load and operating condition requirements. It also provides excellent start and stop performance.

- Intelligent Management: Equipped with an integrated intelligent management system and sensors, the motor enables real-time monitoring and control of operating conditions, including parameters such as temperature, current, voltage, and vibration. This helps effectively prevent and address potential faults.

- Stability and Durability: Constructed with high-quality materials and advanced manufacturing processes, the motor offers exceptional stability and durability. It is capable of long-term operation in complex industrial environments, reducing maintenance and replacement costs.

- Wide Application: Suitable for a variety of industries and scenarios, including food processing, pharmaceuticals, textiles, packaging, printing, injection molding, metallurgy, and mining. It serves as a replacement for traditional asynchronous motors, improving production efficiency and supporting energy savings and emission reduction.

Application of Permanent Magnet Variable Frequency Synchronous Motor

The 750W Permanent Magnet Variable Frequency Synchronous Motor has gained widespread application across numerous industries.

- Pharmaceutical Manufacturing Industry: In the pharmaceutical manufacturing sector, permanent magnet variable frequency synchronous motors are widely used in process equipment such as granulators, mixers, and dryers, as well as in common pharmaceutical packaging production equipment, including automatic packaging machines and weighing packaging machines.

- Packaging Industry: In the packaging industry, these motors are extensively applied in various packaging machinery, including equipment for automatic filling, sealing, sorting, and capping.

- Mechanical Manufacturing Industry: In mechanical manufacturing, permanent magnet variable frequency synchronous motors are utilized in a range of machine tools, automation equipment, tooling machines, and CNC machines, offering high speed, precision, and efficiency.

Furthermore, this motor is also suitable for high-precision, high-speed, and high-efficiency applications such as advanced CNC machine tools, laser cutting, electronic equipment, and communication devices. Overall, the 750W permanent magnet variable frequency synchronous motor’s high efficiency, energy savings, stability, and durability contribute to its exceptionally broad range of applications.

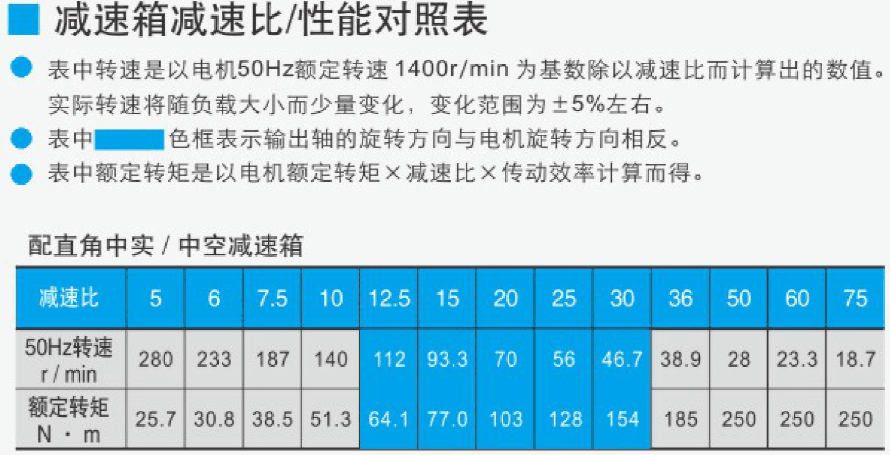

Comparison Table of Reduction Ratio and Performance of 750W Permanent Magnet Variable Frequency Synchronous Motor Gearbox

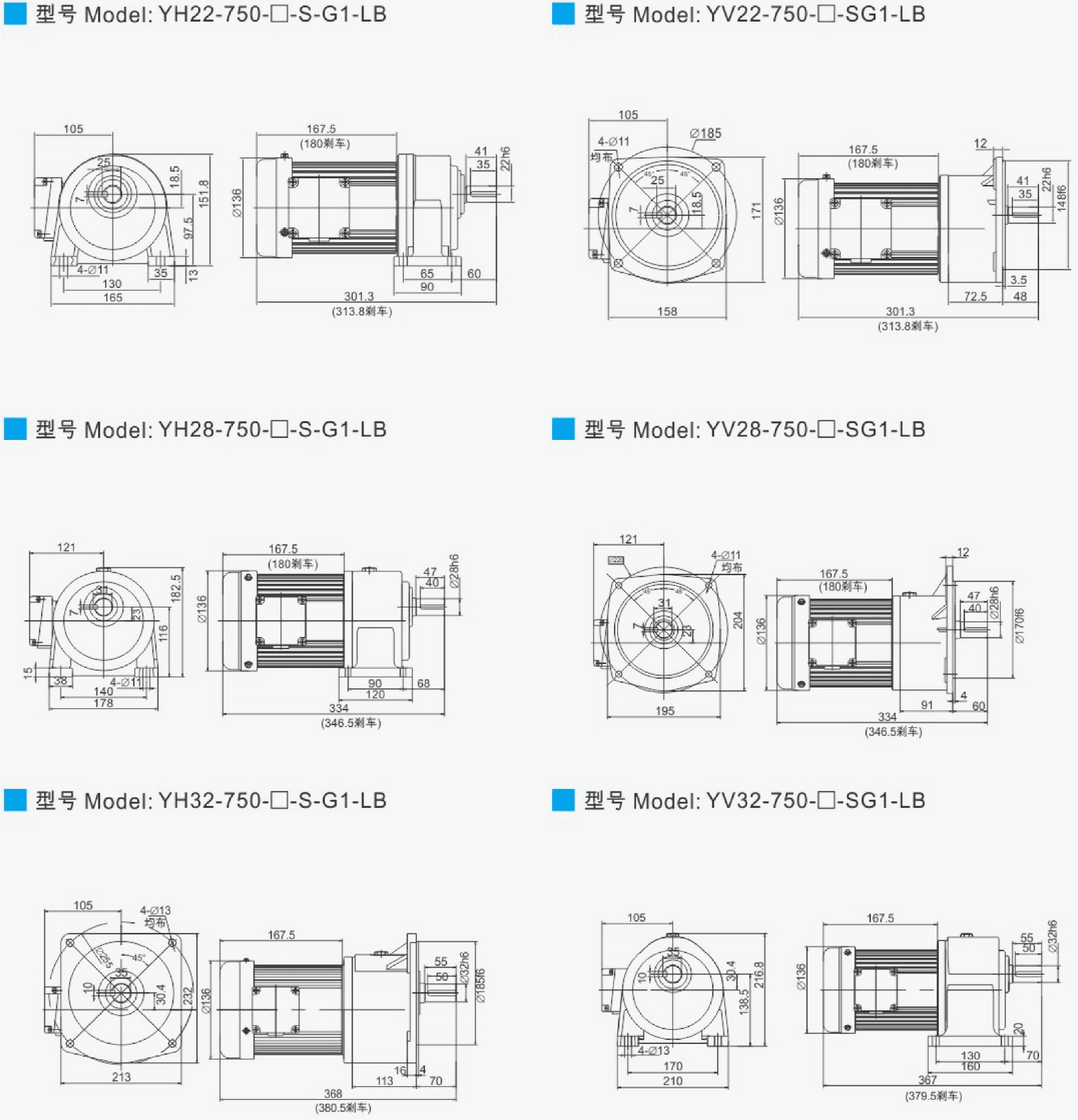

Outline dimension drawing of 750W permanent magnet variable frequency synchronous motor

Advantages of choosing HM Motor

Our company offers highly competitive pricing in the market. We leverage advanced production processes and a robust production management system, utilizing mass production and centralized raw material procurement to reduce manufacturing costs. We prioritize our customers’ interests above all, maintaining production costs within a reasonable range without compromising the quality or performance of our products. As a result, compared to similar products in the market, our pricing demonstrates a strong competitive edge.

Product advantages:

- High Efficiency and Energy Saving: Utilizing permanent magnet synchronous technology, the motor achieves high efficiency and low energy consumption, meeting the national Level 1 energy efficiency standard.

- Wide Voltage Range: The motor operates effectively across a broad range of supply voltages, offering strong adaptability.

- Precise Control: Employing variable frequency speed regulation technology, it provides high control precision to meet the demands of various applications.

- Low Vibration and Low Noise: The motor runs smoothly with minimal noise, making it suitable for environments with stringent noise requirements.

Service advantages:

- Pre-Sales Service: The company offers comprehensive pre-sales support, assisting customers in carefully selecting the products best suited to their needs.

- After-Sales Service: The company has a professional after-sales team providing all-around services, including repairs, maintenance, and upgrades.

- Technical Support: The company maintains a dedicated technical support team, available to provide guidance and consultation at any time, ensuring customers can use the motors with complete peace of mind.

- Quality Assurance: The company’s products come with quality guarantees, backed by a commitment to quality and a robust assurance system, allowing customers to purchase and use our products with confidence.