Products

AC Permanent Magnet Synchronous Motor

AC Permanent Magnet Synchronous Motor Manufacturer

HM Motor is a professional motor manufacturer dedicated to providing customers with high-quality motor products. Among them, the AC permanent magnet synchronous motor is one of our star products.

AC permanent magnet synchronous motor is a new type of motor product that combines the principle of synchronous motor with permanent magnet technology. It has the advantages of high efficiency, low noise, and long lifespan, and is widely used in various fields such as mechanical manufacturing, power industry, and transportation.

As a manufacturer dedicated to the research and production of high-quality motors, we have a professional technical team and complete production equipment. Every AC permanent magnet synchronous motor undergoes strict manufacturing processes and quality control to ensure that the product is always in the best condition.

We firmly believe that only by providing customers with high-quality products and services can we win their trust and support. If you are interested in our exchange of permanent magnet synchronous motor products or have any questions, please feel free to contact us at any time.

AC permanent magnet synchronous motor series

AC permanent magnet synchronous motor Applications

Mechanical Manufacturing

In the field of mechanical manufacturing, AC permanent magnet synchronous motors are used in various machine tools, work equipment, and robots. These motors offer high efficiency and high-speed performance. They also enable quick start and stop, improving production efficiency and reducing machine maintenance costs.Power Industry

In the power industry, AC permanent magnet synchronous motors are commonly used to drive wind turbines or hydroelectric turbines. They can operate with high efficiency and speed, making them the preferred choice in the power industry.Transportation

Many modern transportation vehicles, such as electric cars, e-bikes, and light rail trains, use AC permanent magnet synchronous motors. Compared to other transportation motors, permanent magnet synchronous motors have higher energy efficiency and longer endurance, making them increasingly popular with consumers.Other Fields

AC permanent magnet synchronous motors also have many other applications, such as in medical equipment, aerospace, and electronics. They are often chosen for their high efficiency, precise control, and low noise, which can enhance the overall system performance. As a result, AC permanent magnet synchronous motors have become widely used in many different fields, making them an important piece of modern industrial technology.

Characteristics of AC permanent magnet synchronous motor products

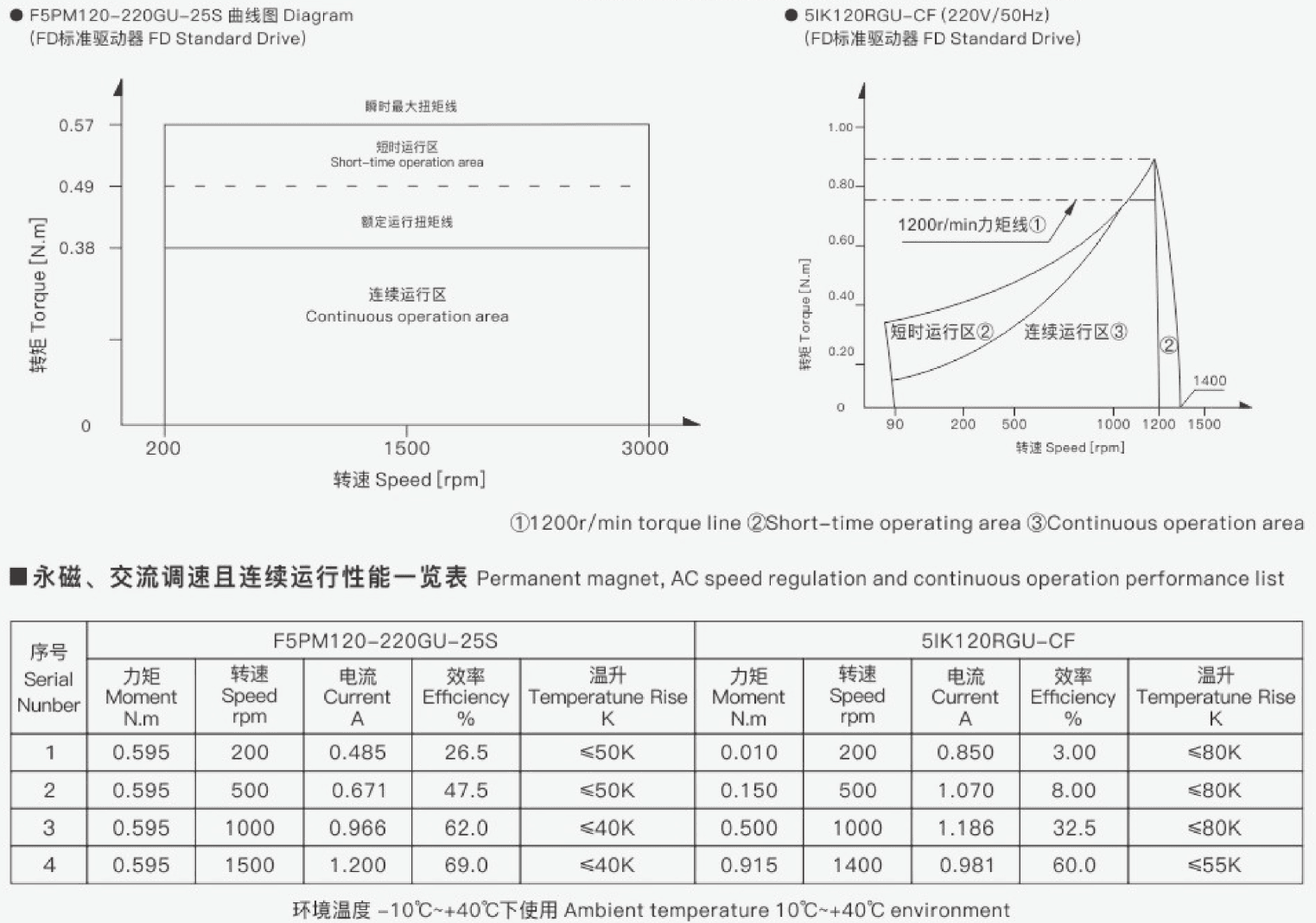

Explanation of characteristic curve of AC permanent magnet synchronous motor

Instantaneous Maximum Torque Line

The maximum torque that the motor can generate when starting and encountering an instantaneous load impact. Exceeding this torque value will trigger the drive’s overcurrent protection, causing a shutdown.Short-Time Operation Zone

The motor can briefly operate within this torque range at different speeds. However, prolonged operation may cause the motor to overheat, leading to motor damage or triggering the drive’s overheat protection, resulting in a shutdown.Rated Operating Torque Line

The rated torque of the motor at different speeds, where the motor can operate continuously for extended periods without issue.Continuous Operation Zone

The motor can run continuously within this torque range at different speeds without overheating or causing damage.

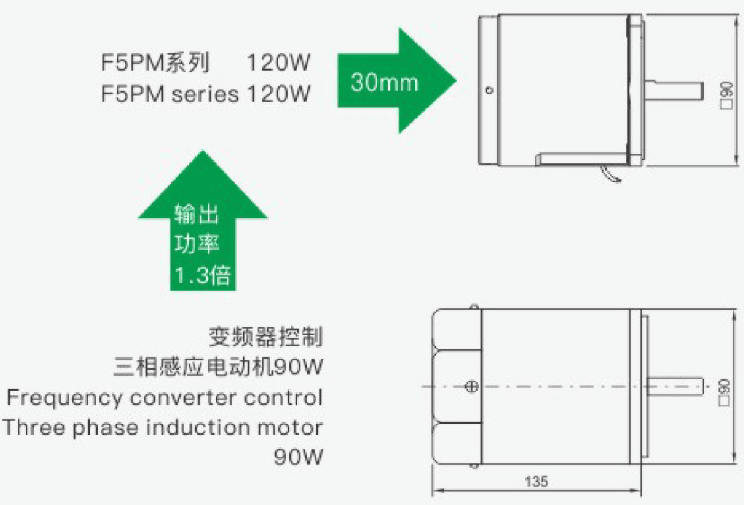

Thin and high-power

The rotor of a permanent magnet motor uses permanent magnets, thus achieving thin and high power; For example, compared to a three-phase induction motor with an installation size of 90, the total length is shortened by more than 75mm, and the output power reaches 1.3 times. If permanent magnet motors are used, it will help achieve miniaturization of the device.

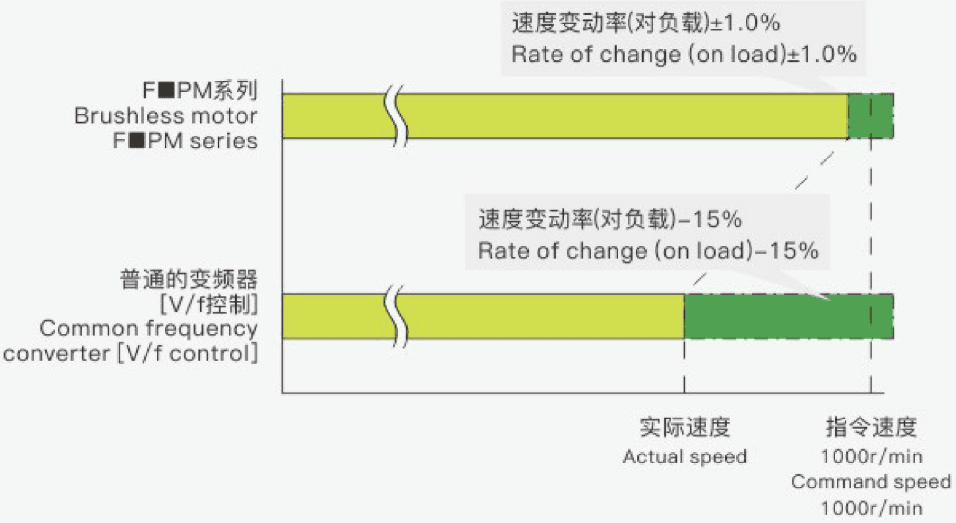

Can achieve stable speed control

The permanent magnet motor continuously compares the set speed with the speed feedback signal from the motor to adjust the voltage applied to the motor; Therefore, even if the load condition changes, it can be adjusted from low speed to the set speed instantly and run at this stable speed. Three phase induction motors controlled by frequency converters do not undergo feedback control, so when the load increases, the speed will significantly decrease; For applications that require high speed stability, it is recommended to use permanent magnet motors.

Low speed and high torque performance

The permanent magnet AC deceleration motor can maintain continuous high torque operation at low speeds and run smoothly.

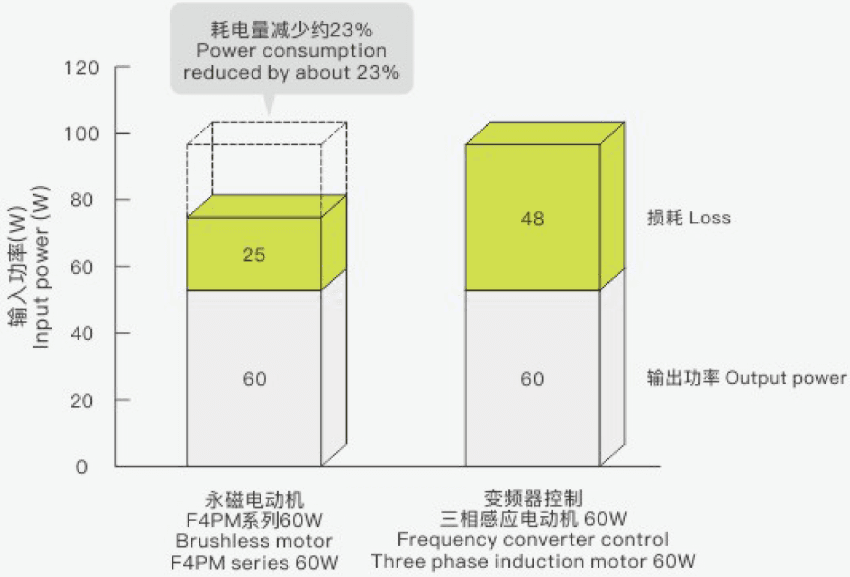

Helps with energy conservation

The rotor of a permanent magnet motor uses permanent magnets, which can reduce the secondary losses of the rotor. Therefore, compared with a three-phase induction motor using variable frequency control, the power consumption is reduced by about 23%, which helps to save energy for the device.

Equipped with protective functions, it helps to ensure the safety of the equipment system

Due to the installation of overcurrent, undervoltage, and phase loss protection functions, the safety of the equipment system during operation can be ensured.

Wide speed control range (FD is currently limited to 2500RPM, but this drive change can be applied to 4000RPM motors)

The speed control range of permanent magnet motors is wider than that of AC speed regulating motors and frequency converters. Unlike AC speed regulating motors, which have torque limitations at low speeds, permanent magnet motors are suitable for applications that require a certain amount of torque from low to high speeds.

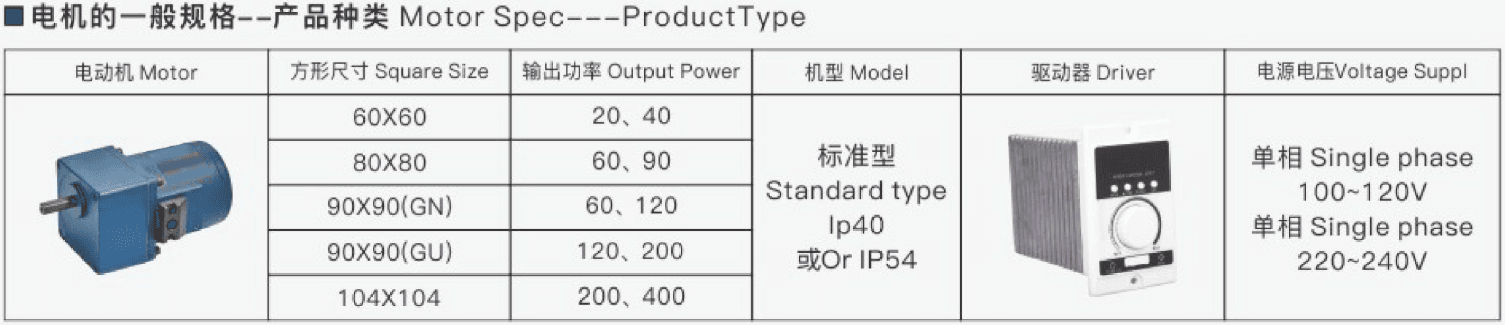

General specifications of AC permanent magnet synchronous motors

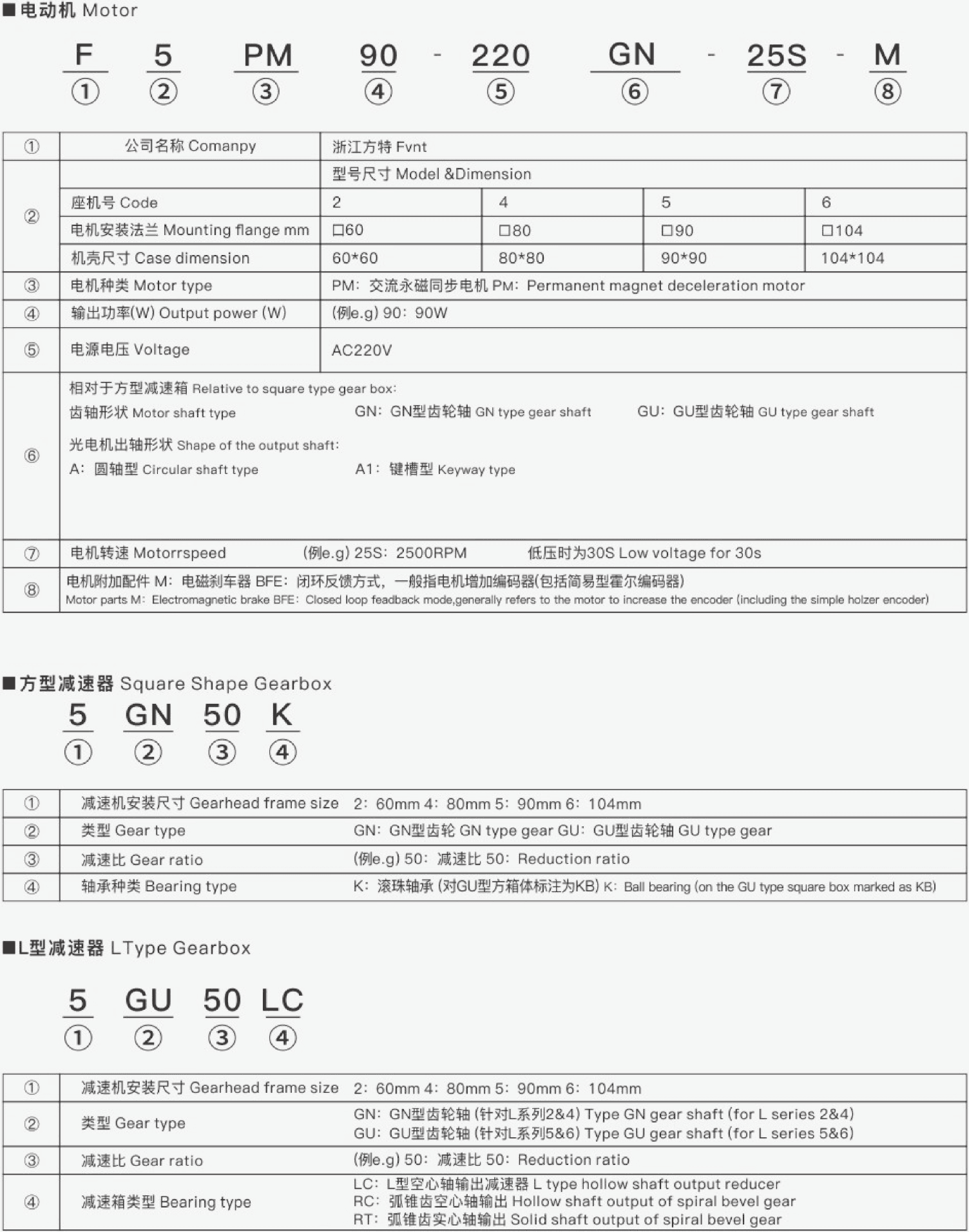

Reading method for AC permanent magnet synchronous motor models