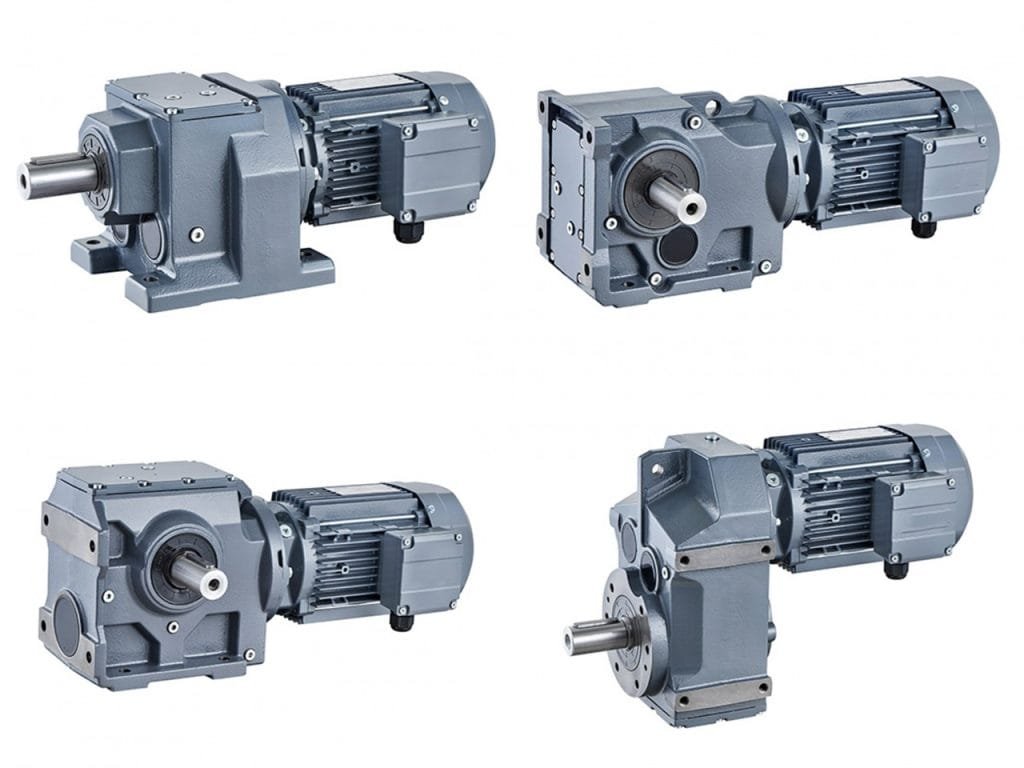

Gear Motors

RFSK Series Helical Gear Motor

- R Helical Gear Motor

- F-series parallel shaft helical gear reducer

- K series helical gear bevel gear reducer

- S series helical gear worm gear reducer

Gear Motors, Gearbox Reducers Manufacturer

HM Motor is a professional manufacturer specializing in the research, development, production, and sales of gear reducers. Our product range covers four major series of gear reducers, including R series helical gear reducers, F series parallel shaft-helical gear reducers, K series helical-bevel gear reducers, and S series helical-worm gear reducers.

We have comprehensive production lines and strict quality control measures to ensure that every gear reducer meets international standards and customer requirements. Here, you can learn about the working principles, technical parameters, and product images of our four major series of gear reducers, as well as receive our professional selection guide.

Our products are widely used in various industries, including metallurgy, mining, cement, paper-making, chemical, food processing, printing, and packaging. If you are looking for high-quality gear reducers, we welcome you to choose HM Motor.

We provide comprehensive pre-sales consultation and after-sales service to ensure you receive timely support and assistance throughout your use of our products. We look forward to offering you excellent products and services.

Performance characteristics of RFSK series helical gear reducer

- Our gear reducers are designed based on a modular system, allowing for easy pairing with various types of electric motors or other power inputs. The same reducer model can be equipped with motors of different power ratings. It’s also easy to achieve combinations between various models.

- High transmission efficiency, with single-stage reducers achieving up to 96% efficiency.

- We offer a wide range of finely divided transmission ratios. Combined models can form larger transmission ratios, resulting in low output speeds.

- Multiple mounting options are available, allowing for horizontal or flange mounting in any position.

Working Environment

- Ambient temperature range: -40°C to 50°C. (For start-up below 0°C, lubricating oil must be heated to above 0°C)

- Altitude not exceeding 1000 meters

- Input speed not greater than 1800rpm, maximum gear circumferential speed not exceeding 22m/s

- Suitable for both forward and reverse operation

- No industry restrictions

- For use under other conditions, please contact our technical department

R Helical Gear Motor

R series gear reducers use high-quality cast iron housings, significantly improving the hardness and impact resistance of the casing. They are designed with a serialized, modular concept, offering finely graded transmission ratios, high transmission efficiency, low energy consumption, superior performance, and wide adaptability.

R series gear reducer technical parameters:

Ratio range:

- R basic type: 3.33 to 289.74

- RX type: 1.3 to 8.65

- R/R combined type: can reach up to 27001

Torque range:

- R basic type: 85 to 18000 Nm

- RX type: 20 to 1680 Nm

Power range:

- R basic type: 0.18 to 160 kW

- RX type: 0.18 to 132 kW

For the basic type, the input and output rotation directions are the same for two-stage reducers, and opposite for three-stage reducers.

F-series parallel shaft helical gear reducer

F series gear reducers are manufactured in accordance with international technical requirements, featuring high technological content, space-saving design, and reliable durability.

F series gear reducer technical parameters:

Power range: 0.12 KW to 200 KW Torque range: 3 N•m to 22500 N•m Output speed range: 0.06 to 374 r/min

F series gear reducer models:

- F type – Standard shaft extension parallel shaft helical gear reducer

- FA type – Shaft-mounted parallel shaft helical gear reducer

- FF type – Flange-mounted parallel shaft helical gear reducer

- FAF type – Shaft-mounted flange-type parallel shaft helical gear reducer

K series helical bevel gear motor

K series gear reducers are a combination of multi-stage helical gears, offering higher efficiency compared to single-stage worm gear reducers.

K series gear reducer technical parameters:

- Output speed range: 0.1 to 530 rpm

- Output torque: ≤18000 N.m

- Motor power range: 0.12 to 200 KW

K series gear reducer connection codes and types:

- K – Foot-mounted, shaft extension connection

- KA – Shaft-mounted connection, foot-supported

- KF – Flange-mounted, shaft extension connection

- KAF – Flange-mounted, shaft-mounted connection

S series helical worm gear motor

The S series gear reducer is one of the four major series of gear reducers. Its unique input and output shaft connection method sets it apart from the other three products, making it irreplaceable. Because of this, it is very popular in the gear reducer industry.

The S series helical-worm gear reducer comes in several basic models, including the SF series, SA series, SAF series, SAT series, and SAZ series.

The gear reducer’s speed ratio ranges from 9.66 to 244.74, with a torque range from 43 Nm to 4200 Nm, and a power output of up to 22 kW.

Instructions for Selection

Gear reducers are typically designed for applications where the number of starts per hour is less than 10, under normal temperatures of 20°C, and at a constant torque. Before selecting the motor model from the selection parameter table, it is important to understand the load and operating conditions of the machine. After determining the operating power, the usage factor \( f_b \) from the parameter table should be selected using the following method:

R/F/K/S Series Selection Process:

1. Determine the operating power of the machine P(KW).

2. Based on the load characteristics of the machine and the number of working hours per day, determine the minimum load factor (f1) (Table 1).

3. Determine the starting factor (f2) based on the number of starts per hour (Table 2).

4. Calculate the total operating factor (fa) (for the S series, also consider the ambient temperature factor (f3) in Table 3).

fA=f1 x f2 (fA=f1 x f2 xf3)

5. Using the operating power and output speed of the gear reducer, select the gear reducer model from the selection table. At the same time, ensure that fA≤ the usage factor provided in the selection parameter table.

Note:

– If users have higher reliability requirements for the gear reducer, they should consider the necessary safety factors or contact us for consultation.

– For radial and axial loads on the output end, please contact our technical department.

– For the use and maintenance of the gear reducer, please refer to the accompanying “Gear Reducer User Manual.”