Feature of Single Step Worm Gear Reducer

- Made with high-quality die-cast aluminum alloy housing, the exterior is lightweight and aesthetically pleasing. The structure is compact with small volume and light weight, saving installation space and resistant to corrosion.

- Excellent heat dissipation performance, safe and reliable with high efficiency.

- High load capacity, smooth transmission, low vibration, and low noise.

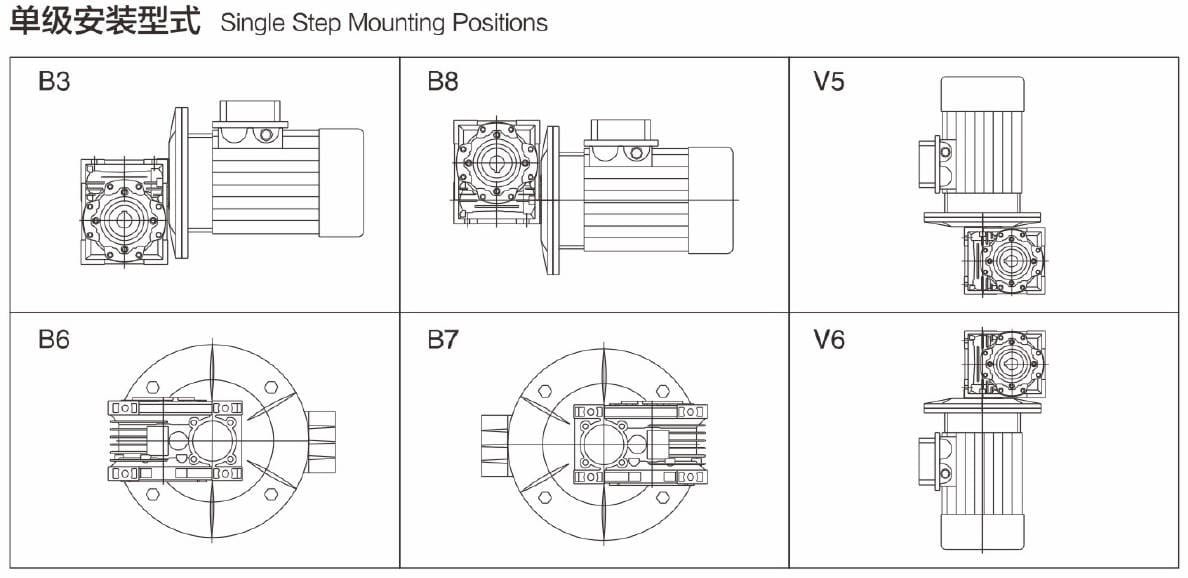

- Features various connection structures for power input and torque output, meeting diverse connection needs. The exterior design and layout of the base mounting holes adapt to multiple installation methods, offering strong versatility.

- Small and medium-sized housings have a fully enclosed structure with strong sealing properties. The lubricating oil inside the housing is less likely to deteriorate or be lost, eliminating the need for replacement and facilitating easy maintenance.

What is single-step worm gear reducer?

The NMRV single-step worm gear reducer is a type of speed reducer widely used in industrial applications, belonging to the RV worm gear reducer family. It consists of a worm wheel and a worm that mesh together to achieve speed reduction. This reducer is characterized by its compact structure, small size, lightweight, low noise, high transmission efficiency, and long service life.

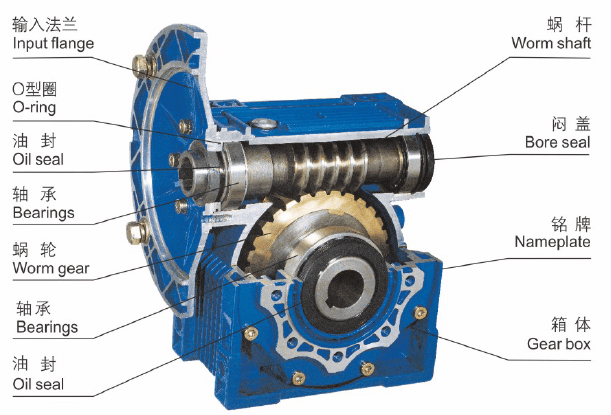

Specifically, the structure of the NMRV single-step worm gear reducer includes:

- Worm Wheel: Usually made of cast iron or steel, featuring high strength, wear resistance, and corrosion resistance. The number of teeth and module of the worm wheel can be selected according to requirements.

- Worm: Typically made of high-strength alloy steel, possessing high hardness and strength. The length of the worm can be selected based on specific needs.

- Bearings: Generally using rolling bearings or sliding bearings to support the rotation of the worm wheel and worm.

- Housing: Usually made of cast iron or steel, designed to protect internal components and provide heat dissipation.

The working process of the NMRV single-step worm gear reducer is achieved through the meshing action between the worm wheel and the worm. When the input shaft drives the worm to rotate, the teeth of the worm wheel engage with the helical line of the worm, thereby reducing the speed of the input shaft and correspondingly increasing the speed of the output shaft. This speed reduction transmission method offers high transmission efficiency and compact size, making it widely used in various mechanical equipment.

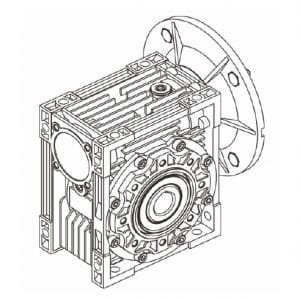

RV Series Worm Gear Speed Reducer Structure View

RV series worm gear reducer manufacturer

HM Motor is a professional enterprise specializing in the manufacturing and sales of industrial mechanical equipment. We offer a wide range of reducers and motor products. With advanced production equipment and comprehensive testing facilities, we ensure the production of high-quality, high-performance RV series worm gear motors, including NMRV worm gear reducers and NMRV-NMRV double-step worm gear reducers.

Our RV series worm gear motors feature simple structure, compact size, high efficiency, and smooth operation, making them widely applicable in mechanical equipment across various industries. We can provide RV series gear motors in different specifications, models, and materials to meet diverse customer needs. Additionally, we offer customized non-standard services, helping customers select the most suitable products and making personalized improvements and adjustments according to customer requirements.

Beyond our products, we provide first-class pre-sales and after-sales services. Our professional technical team offers comprehensive technical support and consulting services, assisting customers in choosing the most appropriate products. In terms of after-sales service, we provide timely and professional maintenance services to resolve any related issues for our customers.

If you are looking for a high-quality, high-performance RV series worm gear motor manufacturer, Hengming Intelligent Equipment is your best choice. Please contact us, and we will be dedicated to serving you.

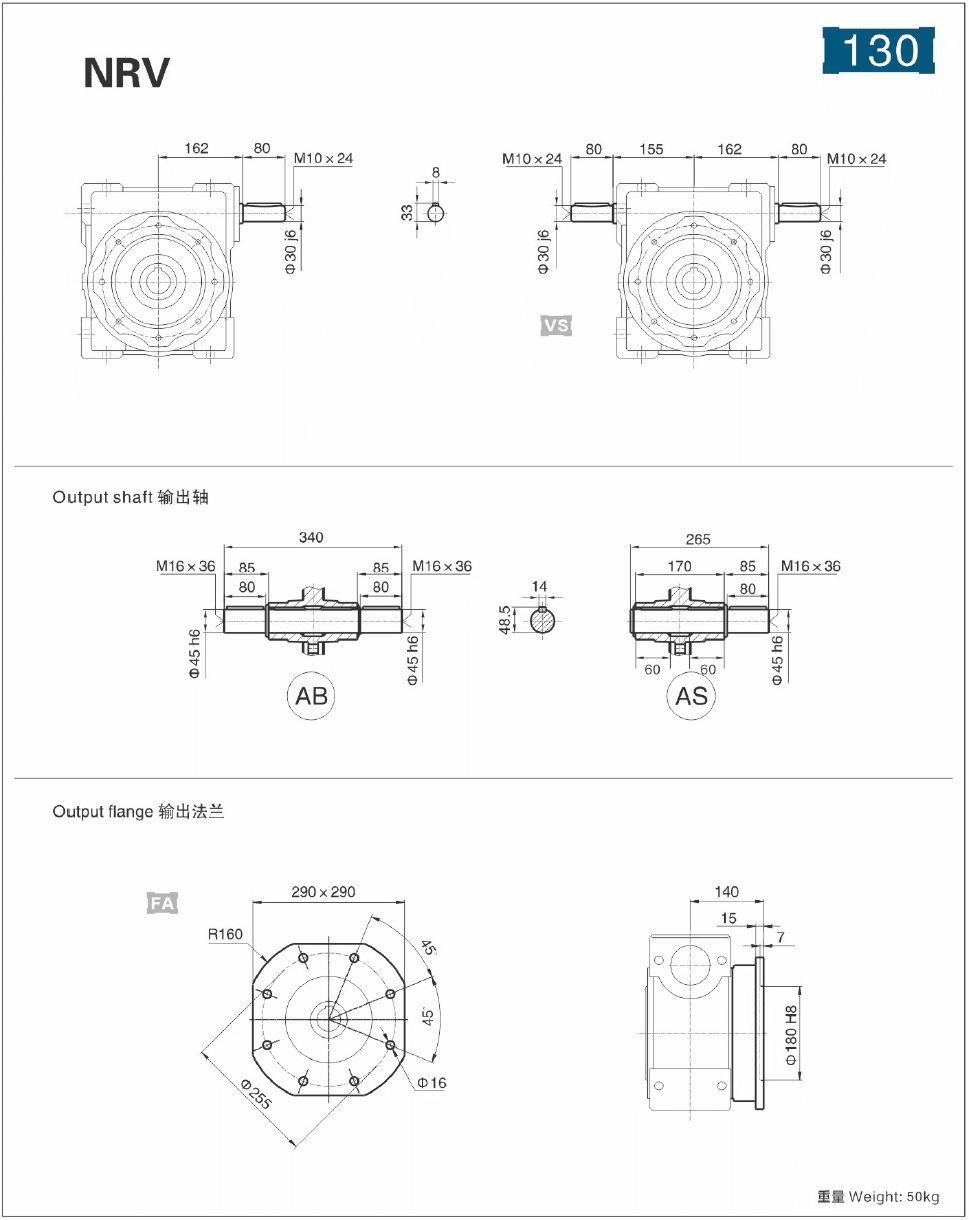

RV series worm gear reducer products

| NMRV | NMRV(For servo motor) |

| NRV..F | NRV..VS |

| NRV | NMRV..F |

| NMRV..VS | NMRV+NMRV |

NMRV/NRV Worm Gear Speed Reducer

| NMRV-063-30-VS-F1 (FA)-AS-80B5-0.55kW-B3 | |||

| NMRV | Worm gear speed reducer | ||

| NRV | Worm gear speed reducer (Mounting input shaft) | ||

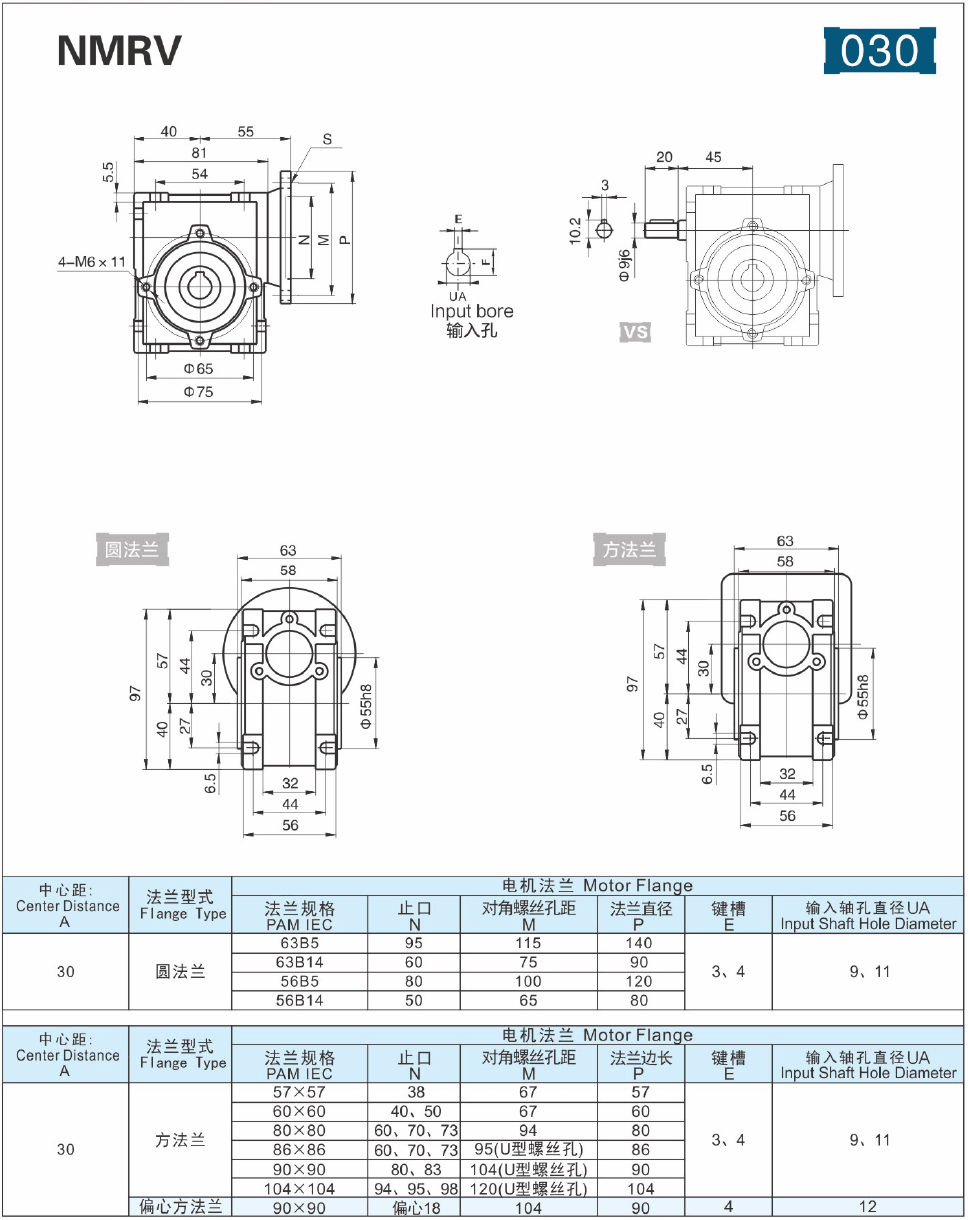

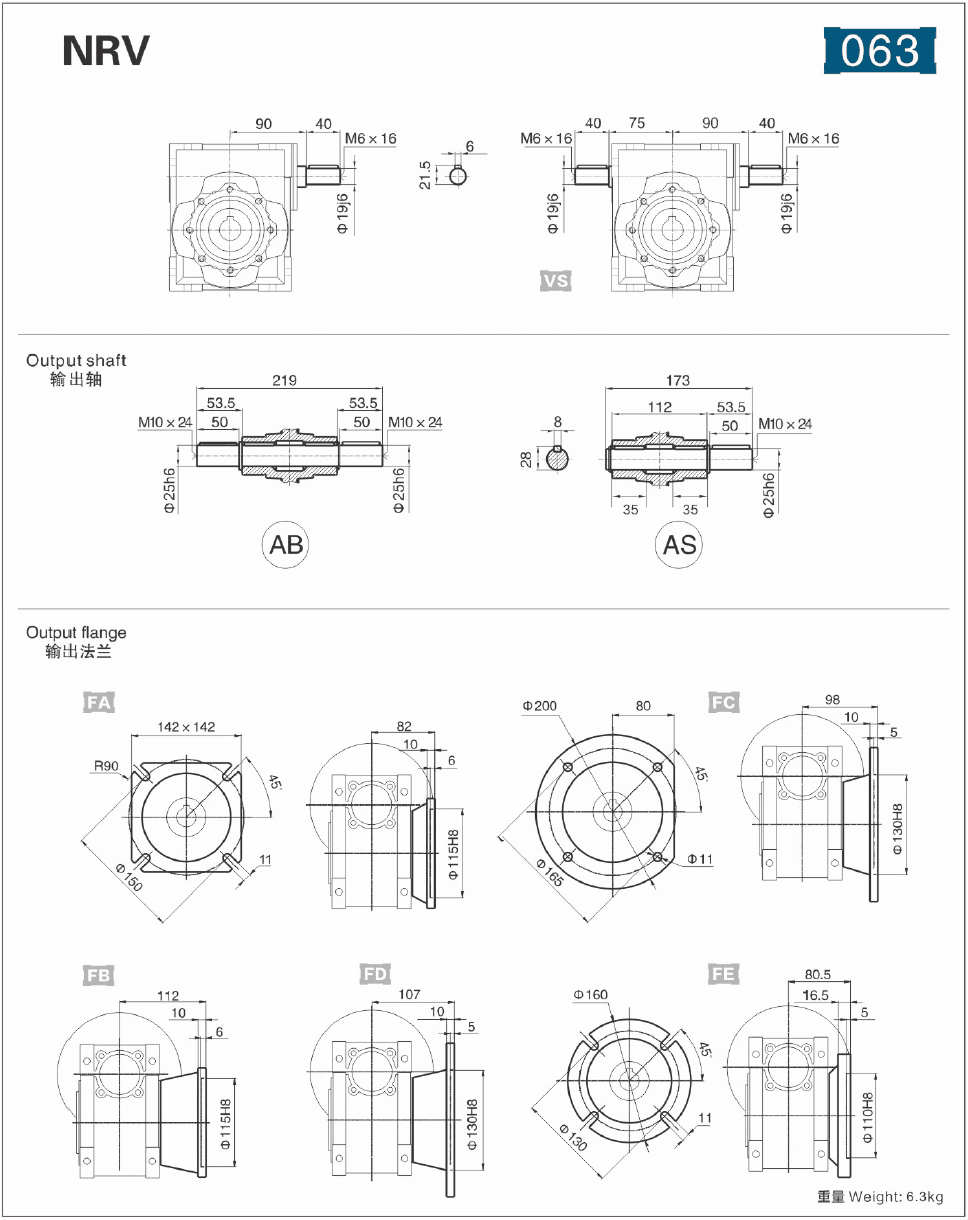

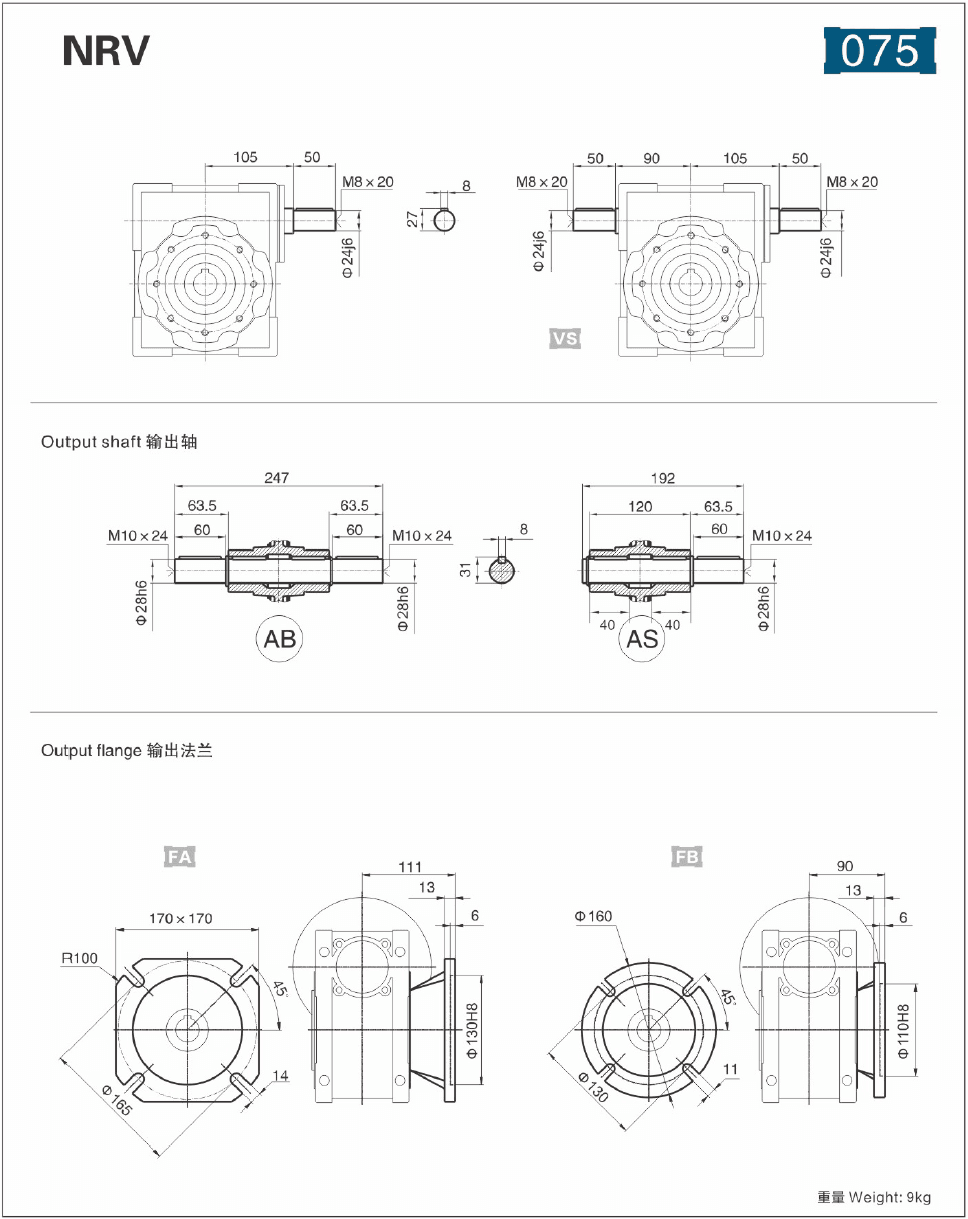

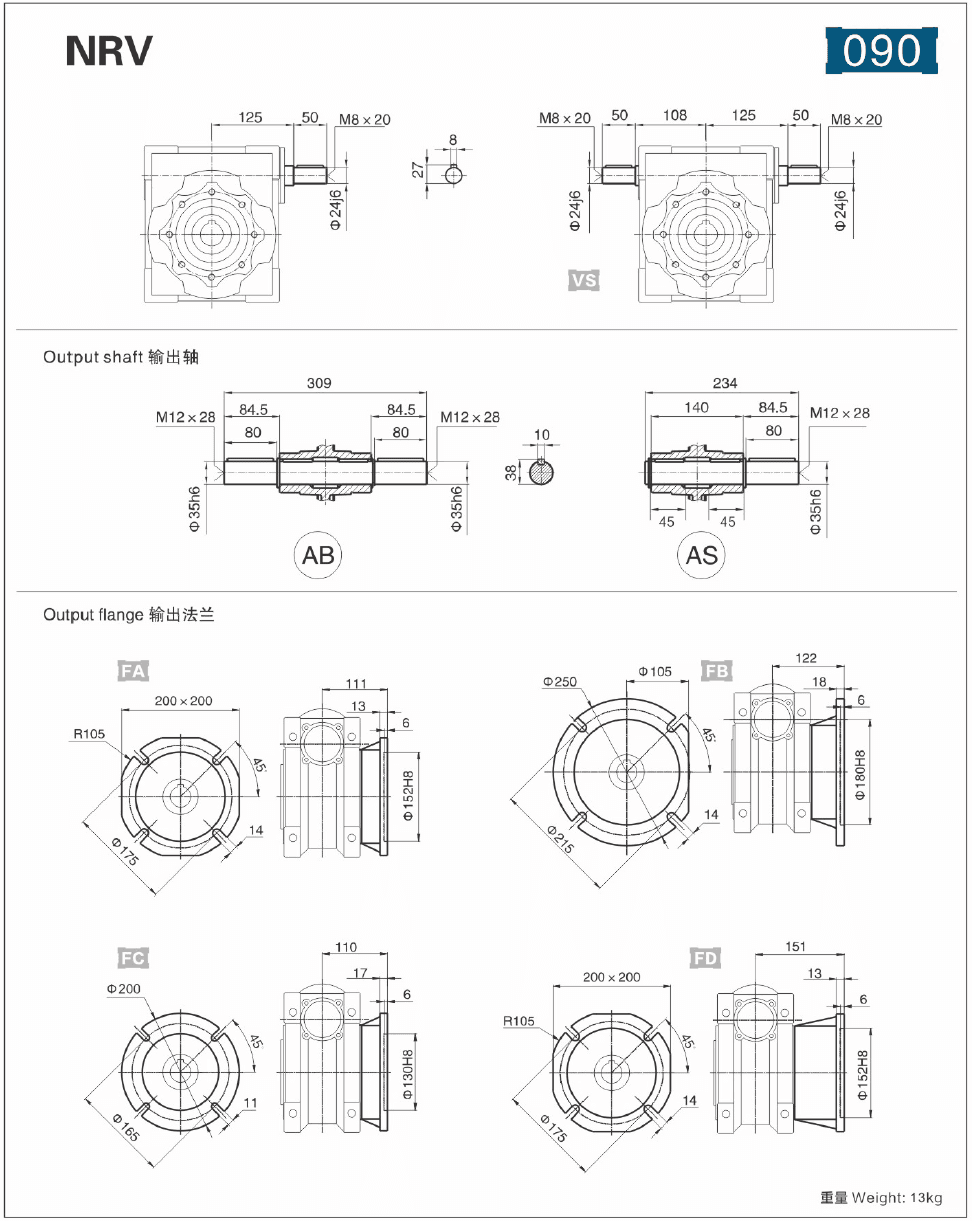

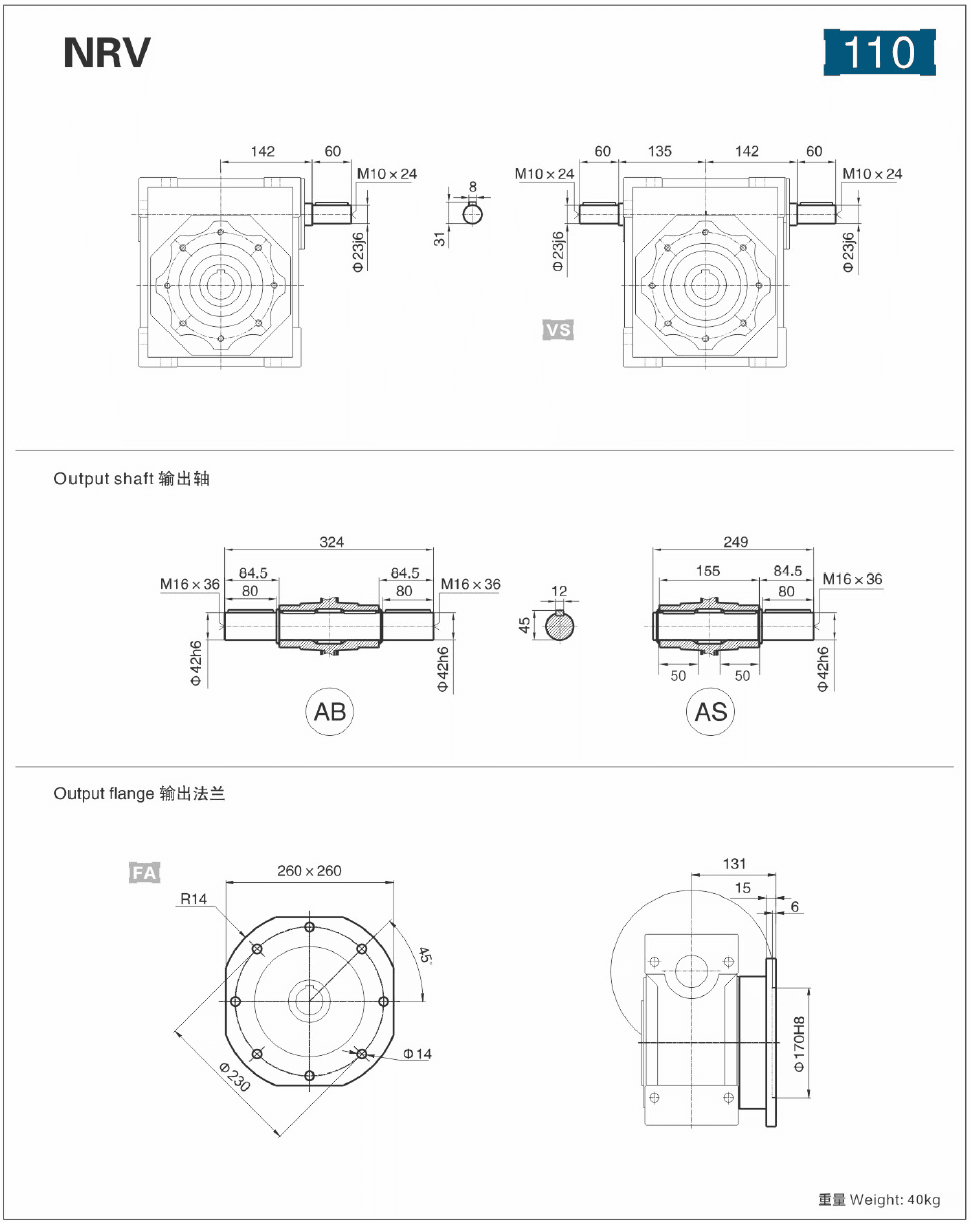

| 63 | Center distance | ||

| 30 | Reduction ratio | ||

| VS | Double input shaft | F1 (FA) | Output flange |

| AS | Single output shaft | AB | Double output shaft |

| PAM | Fitted for motor coupling | 80B5 | Motor mounting facility |

| 0.55kW | Electric motor power | B3 | Mounting position |

Please read before use:

- Load condition

- Speed of rotation or speed ratio (combination with combined speed reducer can get extra low outputting rotational speed )

- Work circumstance (temperature, humidity, corrosion, etc.)

- Space of installation

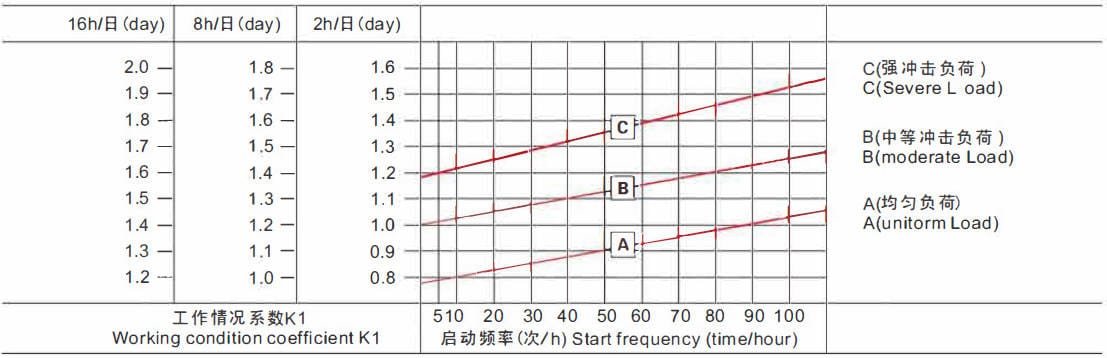

Ensure coefficient of work condition K1 and coefficient of revise K2

- According to the table 1, choose machinery loading type A, B, C

- According to the working time(h/d) and f「equency (times/h ) get the coefficient of work condition K1 from table 1

- According to Table 2, pick up the coefficient of the revised K2

Table 1 Machinery load classification selection

| Using Situation | Example | Load Type |

| Uniform Load | Convey Band (uniform Conveying) | A(uniform Load) |

| Moderate Load | Speed Changed Conveying | B(Moderate Load) |

| Severe Load | Compressor、Pulverizer. etc. | C(Severe Load) |

Table 2 Working condition coefficients K2

| Ambient Temperature | Working Cond巾on Coefficient K2 |

| -10℃~30℃ | 1 |

| 30℃~40℃ | 1.1~1.2 |

Diagram 1 working condition coefficient K1

How to select

- At first, to ensure the value of input machinery load T(torque), multiple K1 and K2 by T, then you can get the value of output torque, on the basis of which, also consider the speed of output rotation or speed ratio, then you can choose a specification

- You can calculate the output torque based on the known input power, reasonable ratio or speed of output rotation, then you can choose specification.

Example for model selection

Ex1. General conveyor belt (uniform load)

- Torque: 19N.m

- Turning time: 8hs/day

- Speed of rotation: about 55r/min

- start frequency: 1 Otimes/h

- Ratio:1/25

- Temperature:25°C (indoor) Connect with motor direct

1. According to Table 1, ensure the type of load

Type of load: load-bearing uniform without impact, choose A;

2. According to diagram 1, choose the point 1 Otimes/h on the intersection A, we can get the K1 =1 of turning time 8hs/d;

3. According to the table 2, get the K2=1;

4. The value of torque is 19 x K1 x K2=19 x 1 x 1=19N.m,choose the closest 19N.m reducer.

Choose selection: NMRV30-1/25

Input power = 0.18kw, the speed of output rotation is= 56r/min,

the value of output torque is 21 N.m

Ex2.con conveying belt( moderate load)

- Torque: 65N.m

- Turning time: 16hs/d

- Speed of rotation: about 21 r/min

- Start frequency: 1 OOtimes/h

- Ratio: 1/60

- Temperature: 35°C (indoor) Connect with motor direct

1 . According to Table 1, ensure the type of load

Type of load: light load-bearing, choose B;

2. According to diagram 1, choose the point 1 OOtimes/h on the intersection B, then you can get the K1 =1.65 of turning time16hs/d;

3. According to the table 2,get the K2= 1.15;

4. The value of torque is 65 x K1 x K2=70 x 1.65 x 1.15=123N.m, choose the closest 123N.m reducer ..

Choose selection: NMRV63-1/60.

Input power = 0.55kw, the speed of output rotation =23.3r/min,the value of output torque is 140N.m

| Our Enterprise | NMRV025 | NMRV030 | NMRV040 | NMRV050 | NMRV063 | NMRV075 | NMRV090 | NMRV110 | NMRV130 | NMRV150 |

| NMV030 | NMV040 | NMV050 | NMV063 | NMV075 | NMV090 | NMV110 | NMV130 | NMV150 | ||

| Domestic | NMRV025 | NMRV030 | NMRV040 | NMRV050 | NMRV063 | NMRV075 | NMRV090 | NMRV110 | NMRV130 | NMRV150 |

| NRV030 | NRV040 | NRV050 | NRV063 | NRV075 | NRV090 | NRV110 | NRV130 | NRV150 | ||

| WJ25 | WJ30 | WJ40 | WJ50 | WJ63 | WJ75 | WJ90 | WJ110 | WJ130 | WJ150 | |

| FCNDK25 | FCNDK30 | FCNDK40 | FCNDK50 | FCNDK63 | FCNDK75 | FCNDK90 | FCNDK110 | FCNDK130 | FCNDK150 | |

| FCNK30 | FCNK40 | FCNK50 | FCNK63 | FCNK75 | FCNK90 | FCNK110 | FCNK130 | FCNK150 | ||

| JRSTD025 | JRSTD030 | JRSTD040 | JRSTD050 | JRSTD063 | JRSTD075 | JRSTD090 | JRSTD110 | JRSTD130 | JRSTD150 | |

| JRST030 | JRST040 | JRST050 | JRST063 | JRST075 | JRST090 | JRST110 | JRST130 | JRST150 |